Advantages:

1. Three servo motor versions, high-speed output, stable operation, time-saving, and film.

2. Interface features easy and quick setting and operation.

3. Self-failure diagnosis, clear failure display.

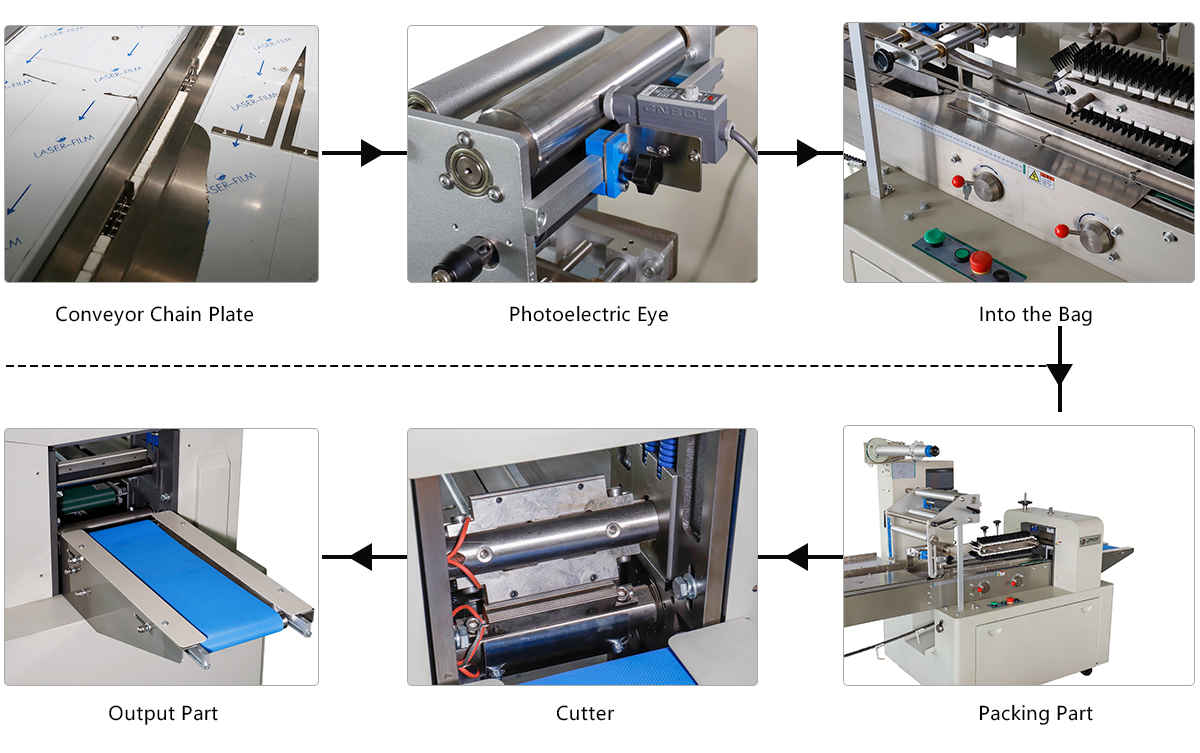

4. High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

5. Temperature-independent PID control, more suitable for packaging different materials.

6. Positioned stop function without sticking knife or wasting film.

7. Simple driving system, reliable working, convenient maintenance.

8. All control is realized through software, easy for function adjusting and technical upgrades.

Technical feactures:

1. This equipment could be connected to the production line directly.

2. Full automatic feeding-extruding-cutting-packing-date printing, all in one line.

3. Multi-variable frequency speed control, servo drive control, stable running, high control preciseness, and low energy consumption.

4. Colored touch screen, easy operation and adjustment, fault display, and data storage function to operate easily for changing different size products.

5. Equipment designed by products' characteristics to avoid extruding products. When the product is in a fail condition, it can remove the unacceptable without stopping the machine, guaranteeing the packing process continuously and stably.

6. Full stainless steel structure, humanized design, easy installation, easy disassembly, and easy maintenance.

Product Name | Syringe Packing Machine |

Product Size | L 120-500mm, W 35-200mm, H 5-70mm |

Packing Capacity | 32-160 bags/min |

Packing Film Width | 90-450mm |

Packing Material | Composite films such as OPP/PE, OPP/CPP |

Net Weight | 600kg |

Power Supply | 220V 50Hz |

Total Power | 3.2kw |

Outer Size | 4000×950×1600mm |