Specifications of this Energy Bar Packaging Machine

—

Mode | UPX-QKL |

Product Name | Automatic Energy Bar Packaging Machine |

Master Conveyor Belt Width | 600/800/1000/1200 mm |

Packing Capacity | 50-600 bags/min |

Power Supply | 1ph-220V-50Hz or 3 ph-380V-50Hz |

Total Power | To be finalized according to user's actual situation. |

Product Size | Customized |

Introduction of this simple Energy Bar Packaging Machine

—

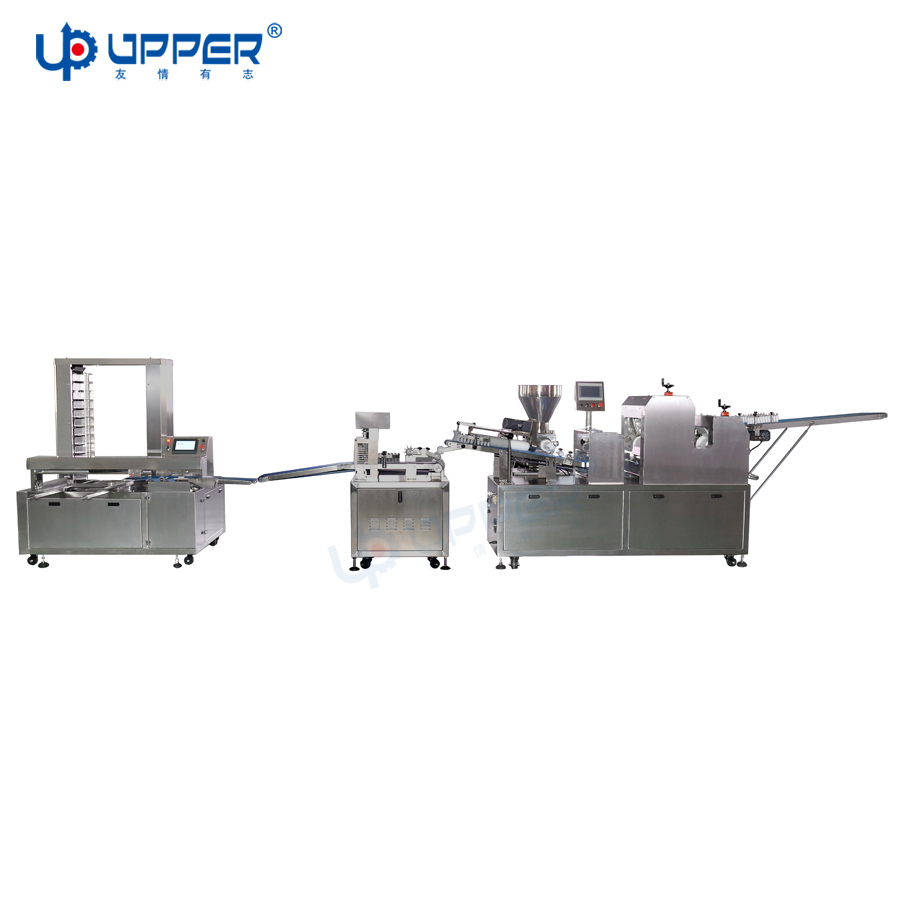

● This packaging line consists of three structures: feed, material management and packaging. Each one has corresponding speed adjustment and product size information input.

● The feeding structure is specially designed to effectively protect the integrity of the whole energy bar.

● High-precision and sensitive SICK electric eye tracking system, accurate material position control.

● This product adopts stainless steel structure, humanized design. Which makes installation, disassembly and maintenance simple and fast.

Advantages

—

【Nice Price】

● Supply by factory directly.

【Packaging Line Solutions Customization Is Available】

● Experienced engineer team is always here for you. (over 20 years experience in the packing machine industry)

【Quality Assurance】

● Products with CE, ISO, Patent, Quality Assurance Certifications. High-tech enterprises certificate.

【Fast Delivery & Professional After-sales Service】

● With more than 50 workers in the production team.

【Time-saving, Cost-saving, High Efficiency】

● This equipment could be connected with the production line directly. Full automatic feeding-alignment-orienting-distributing-packing, all in one line.

【Machines Works Stable】

● Adopt multi-variable frequency speed control, servo drive control.

【Easy To Operate】

● Adopt colored touch screen, easy operation and adjustment, fault display, data storage function, to operate easily for changing different size products.

【Production Guarantee】

● Equipment designed by product characteristics to avoid products extruding. When the product is in fail condition, remove unacceptable one without stopping machines.

Why Need Automatic Energy Bar/Chocolate Bar Packaging Machine?

—

● Increase the packing capacity.

● Increasing the efficiency of packing chocolate bars and candy bars.

● You can reduce your time packing chocolate bars and candy bars using an automatic packing machine.

● Reducing the number of employees in the production line as most functions are automatic.

The machine will boost chocolate production and maximize profits in the long run.

How to Adjust the Energy Bar Packaging Machine?

—

● Ensure that the raw materials are in plenty of supply to ensure that the machine does not stop.

● Ensure that you enter the correct packing parameters in the PLC control system to allow smooth operations.

●Confirm whether the electrical wires are loose, and check whether they are well connected.

● Regular cleaning and maintenance of the machine will keep the machine in perfect working conditions at all times.

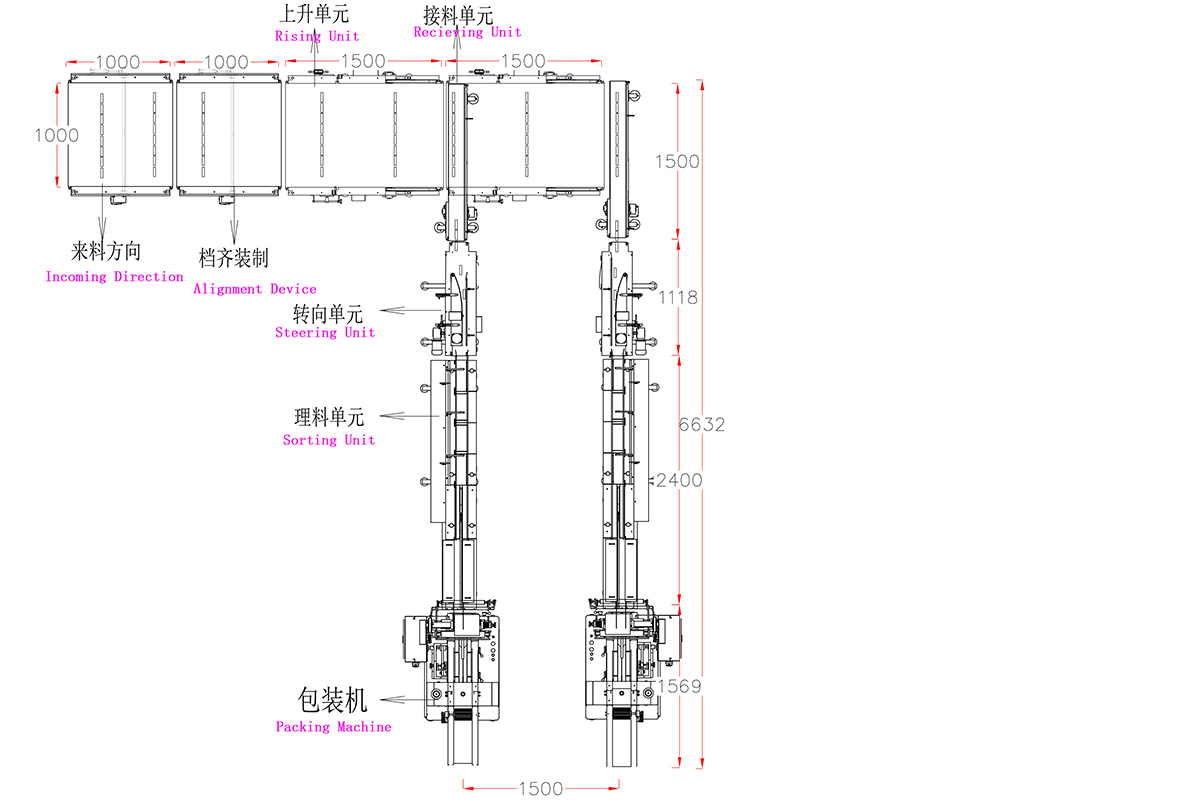

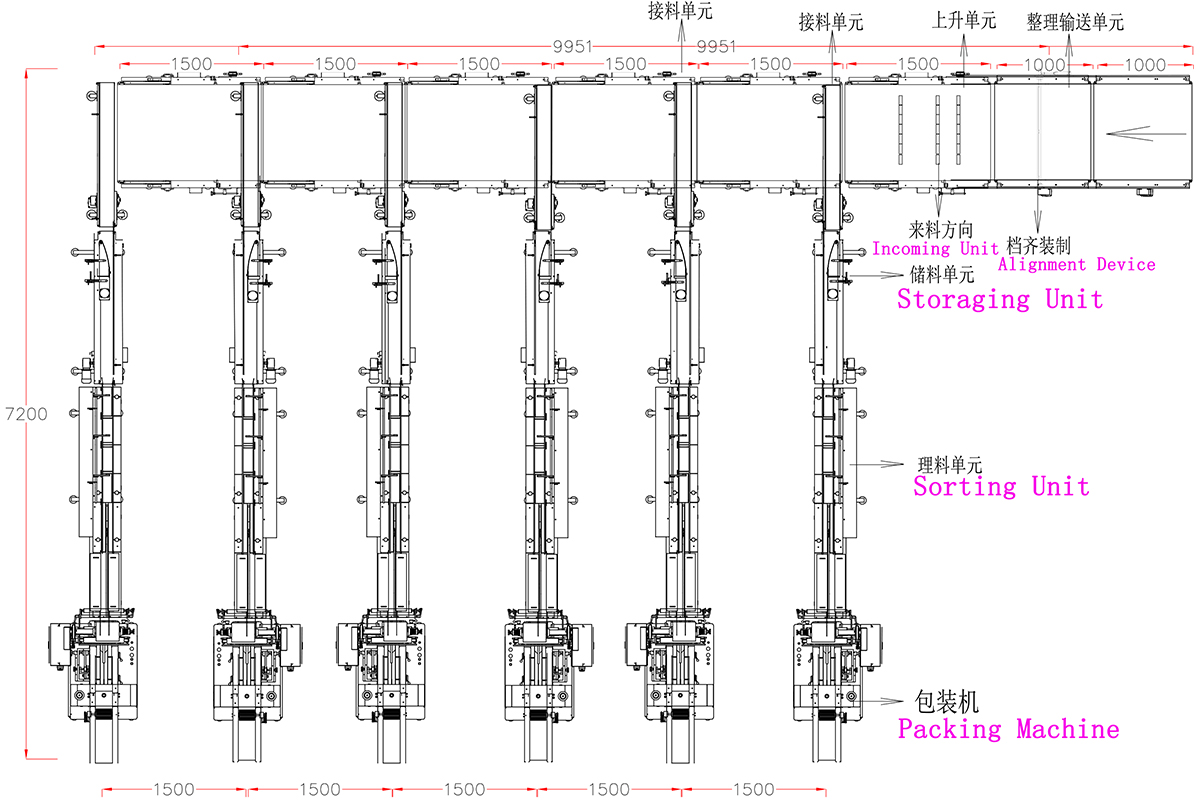

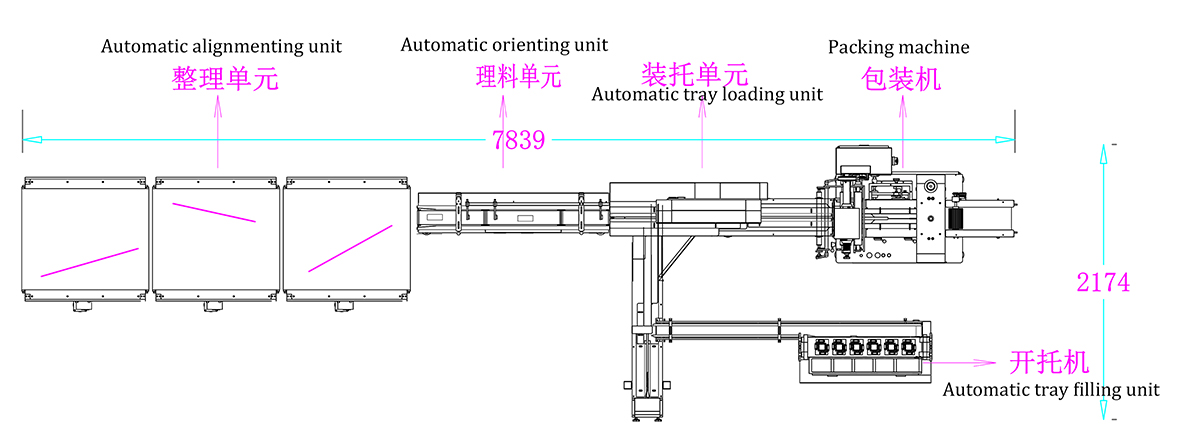

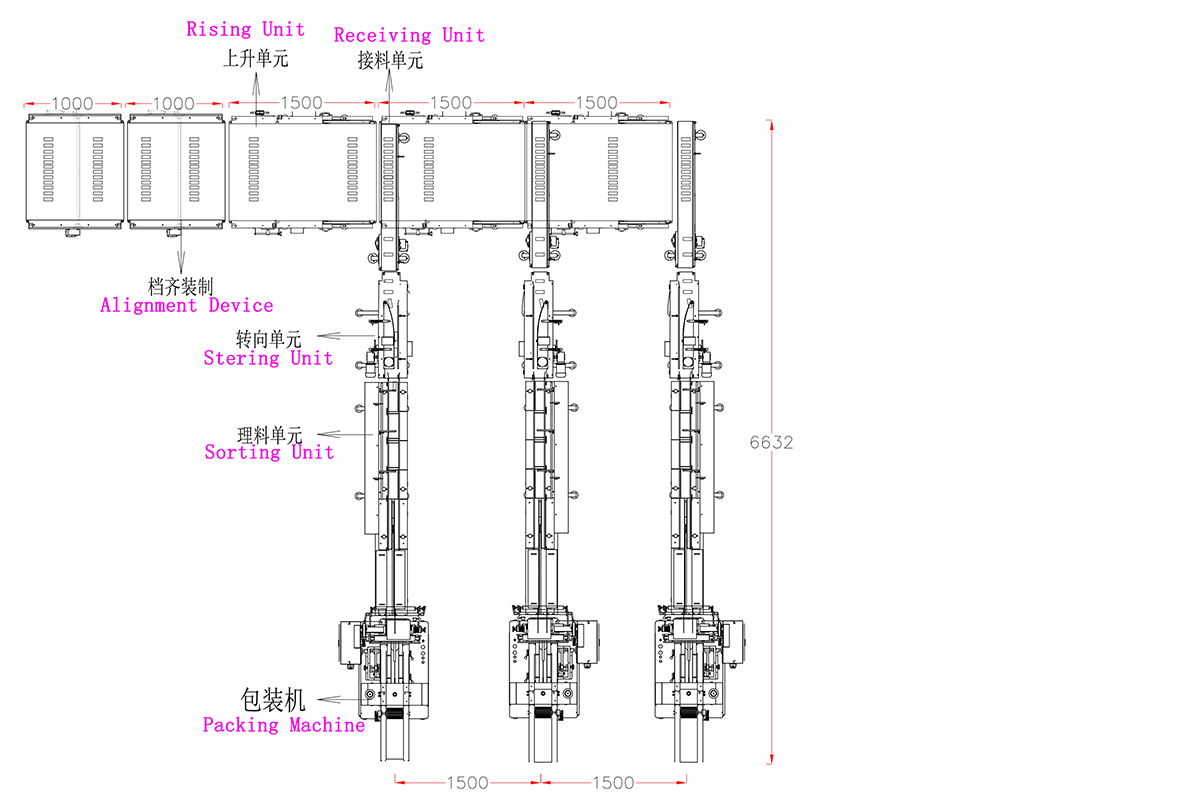

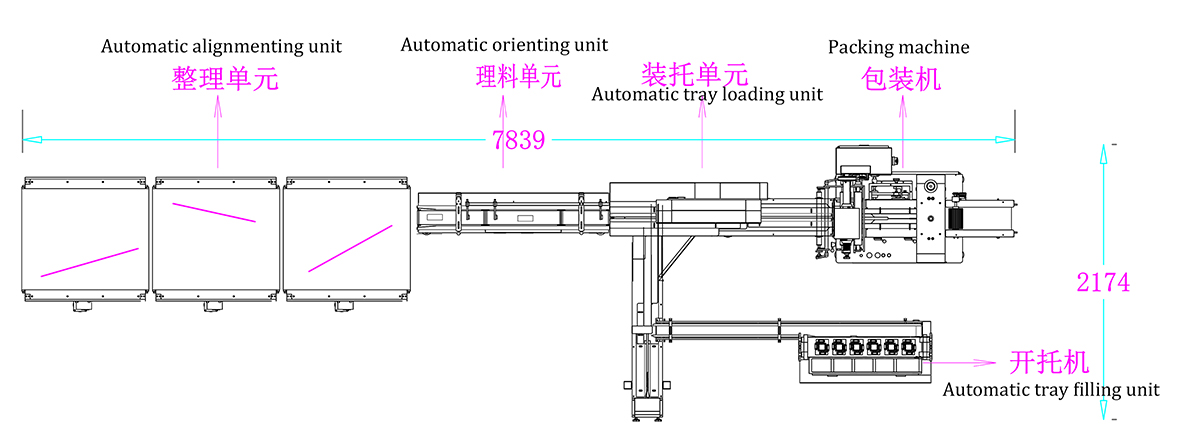

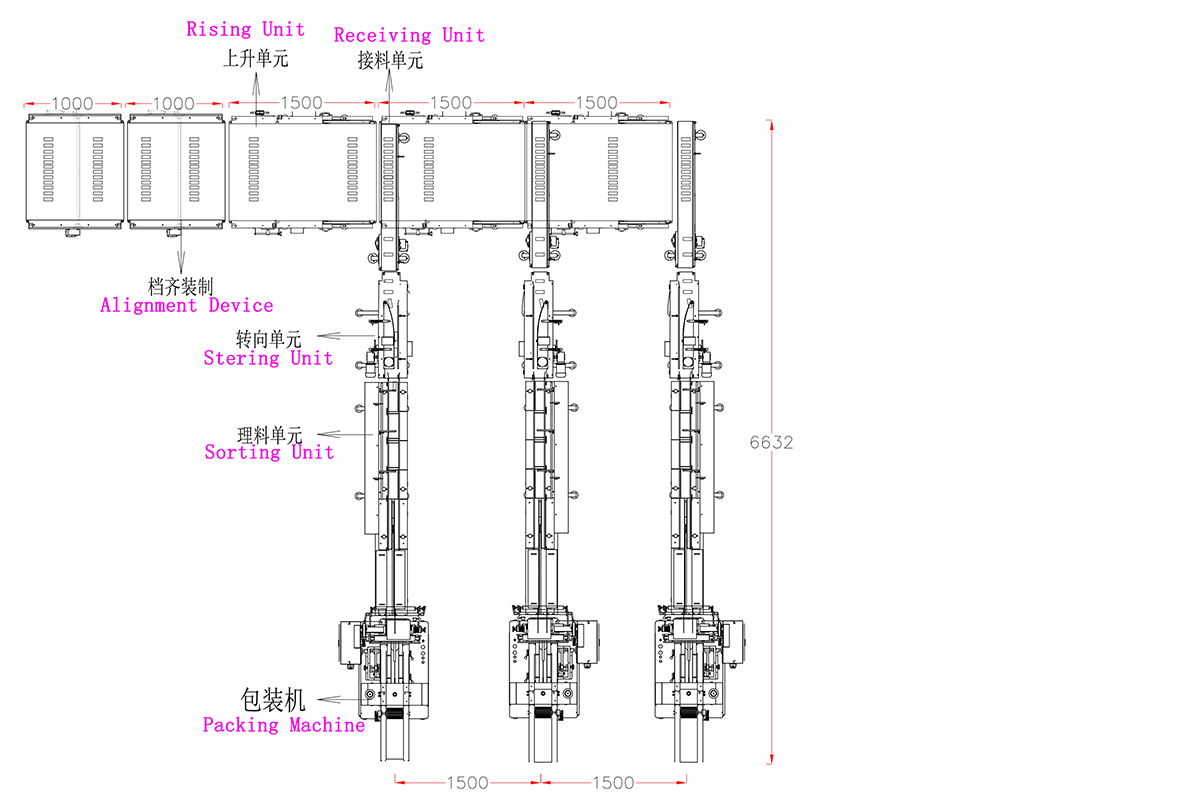

The Full Automati Energy Bar Packaing Line Mainly Include:

—

● Automatic feeding conveyor

● Power baffle

● Steering structure

● Candy bar/Chocolate bar horizontal flow packing machine

● Candy bar/Chocolate bar carton box packing machine

Choose the Automatic or Semi-auto Chocolate Packing Machine?

—

Semi-auto energy bar packaging | Automatic energy bar packaging |

Small production | Big production capacity |

Manually feeding the energy bar/chocolate bar | Directly connect the energy bar/chocolate bar production machine |

Handling, a certain degree of wear and tear | Hand contact and handling effectively reduce wear |

Operation technicians must be familiar with packaging machinery foundation | Intelligent operation, few manual operations, saving time |

Lower machine cost | Valuable price |

The footprint of the machine is relatively small | Customized footprint |

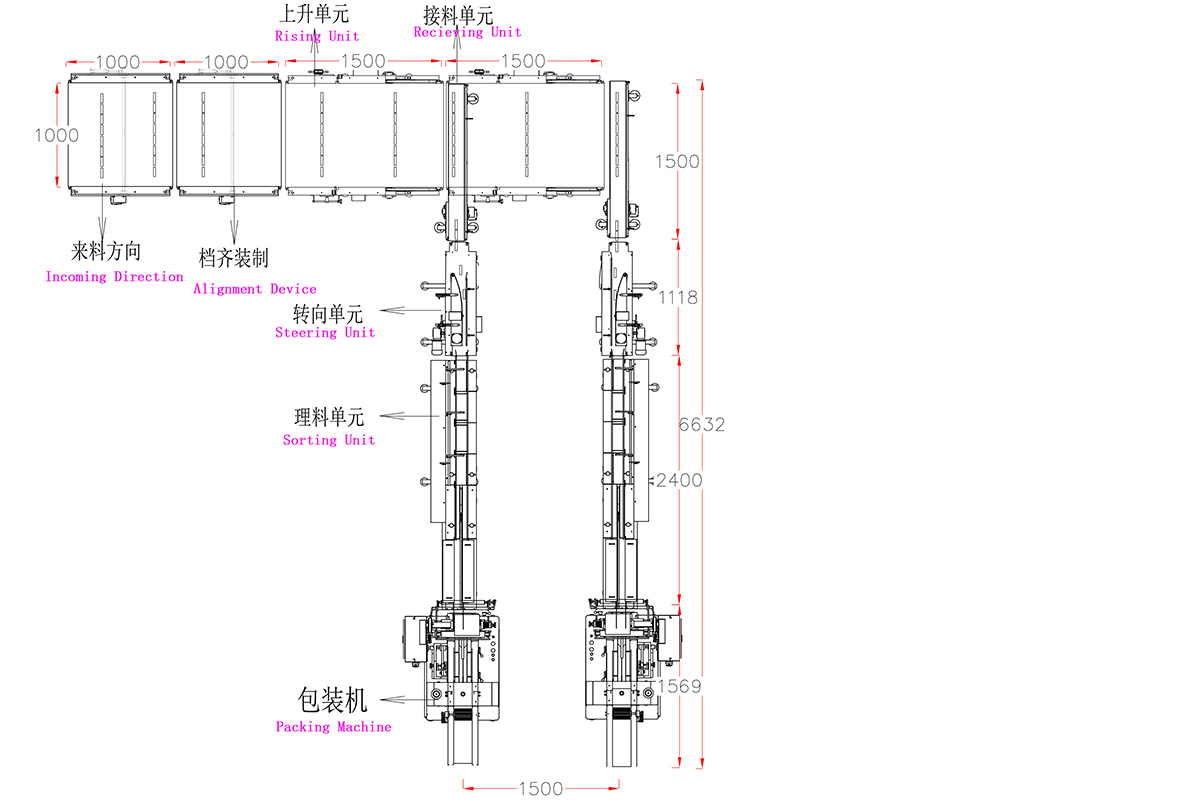

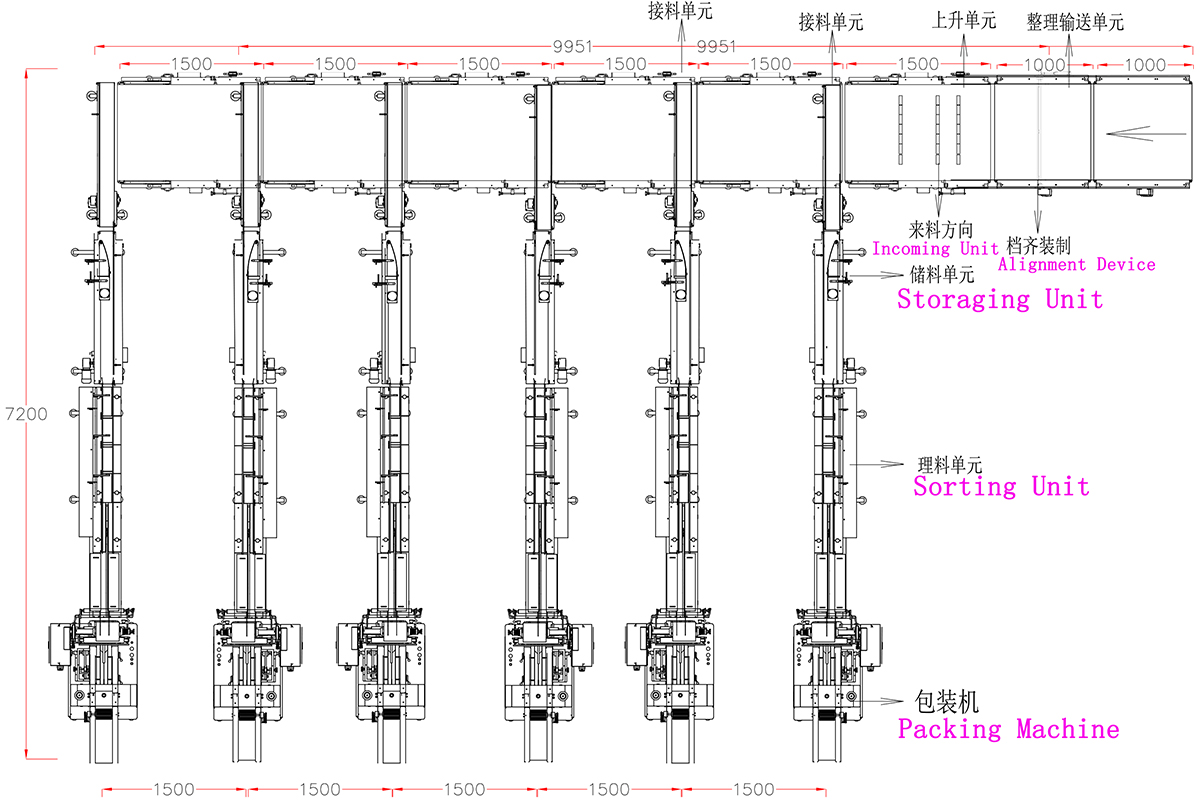

There Are Two Designed Ways of the Automatic Energy Bar Packaging Machine:

—

● Automatic power baffle energy bar/chocolate bar feeding packing line. (Due to the short bar's length and high-speed requirement)

● Automatic ascending and energy bar/ chocolate bar feeding packing machine. (Due to the no contact with materials' packing requirement)

Please Check Some of Our Energy Packaging Layout Projects:

—

Please Send Us Your Requirements, We Will Send You CAD Drawings and Quotations Accordingly.

—

● Product Incoming Methods: such as neat incoming materials, manual pours, scattered incoming materials, preferably with video.

● Product Characteristics: fragile, regular, soft, sticky, etc., best with samples pictures.

● Packing Method: one pack, two packs up and down, etc., preferably with pictures.

● Production Capacity: how many products per minute?

● What is the requirement for packing speed?

● Do you have requirements for the size of the venue?

Applications

—

Mainly applied to meet the chocolate, candy, energy bar, wafer cake, green bean cake rules of solid objects material such automatic high-speed transport, sotring, feeding and automatic packing products.

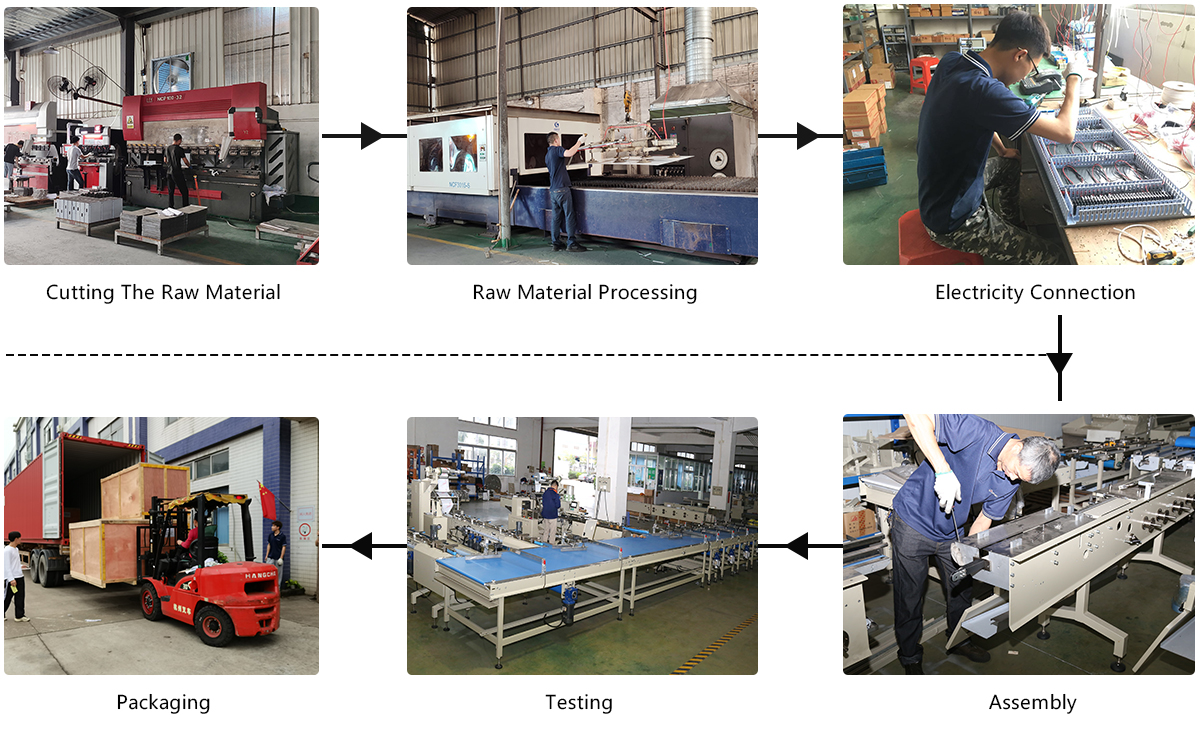

Production Process