Main Performance and Structure Features:

—

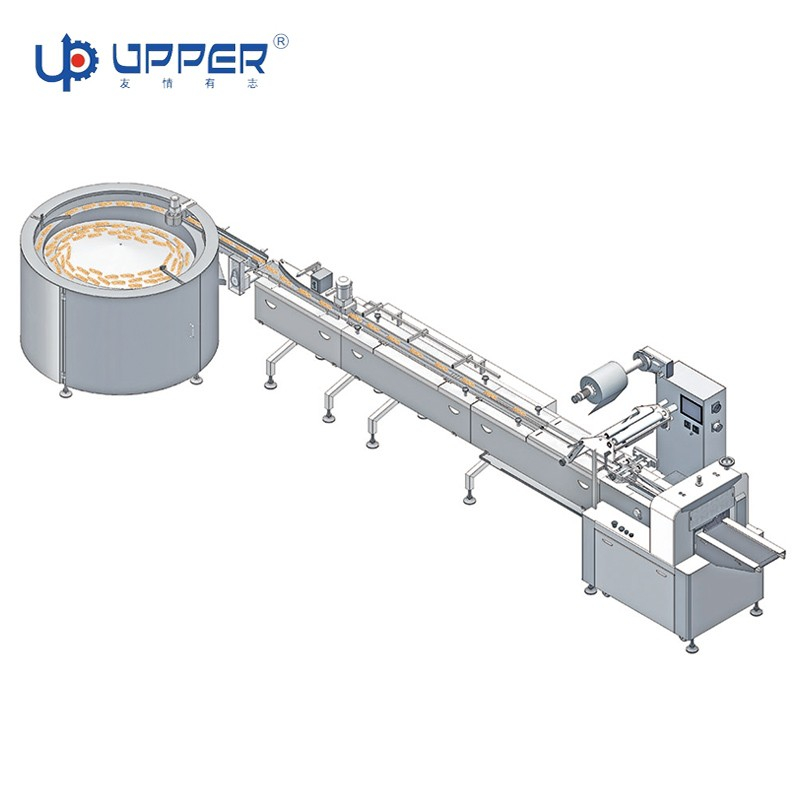

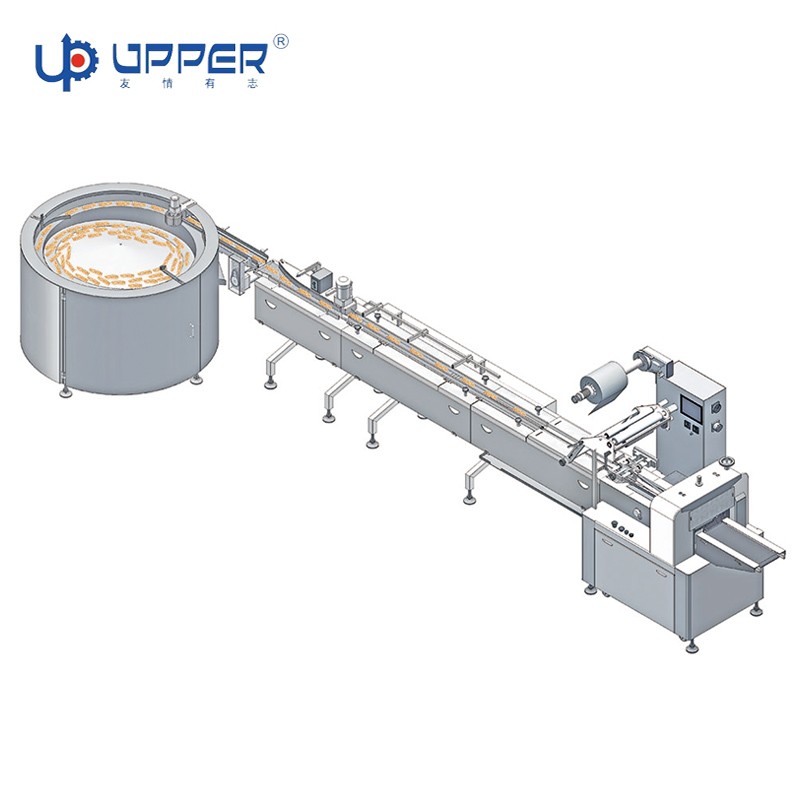

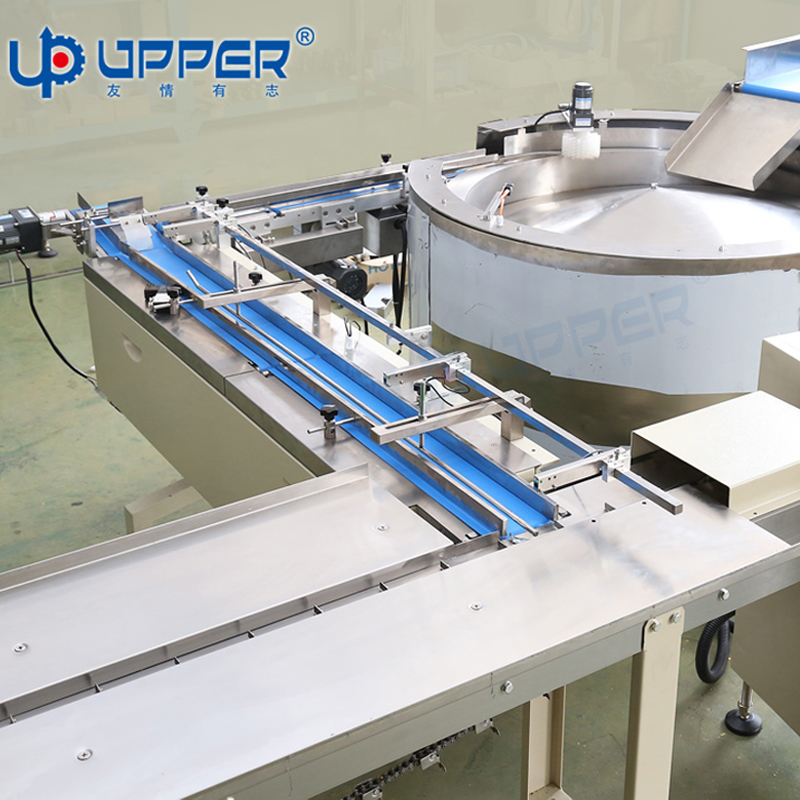

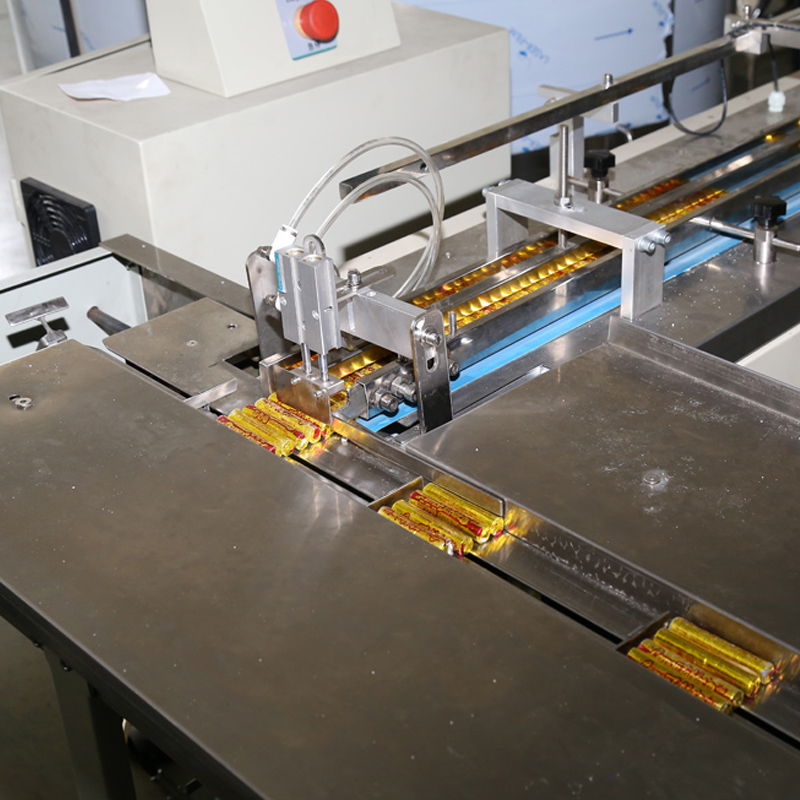

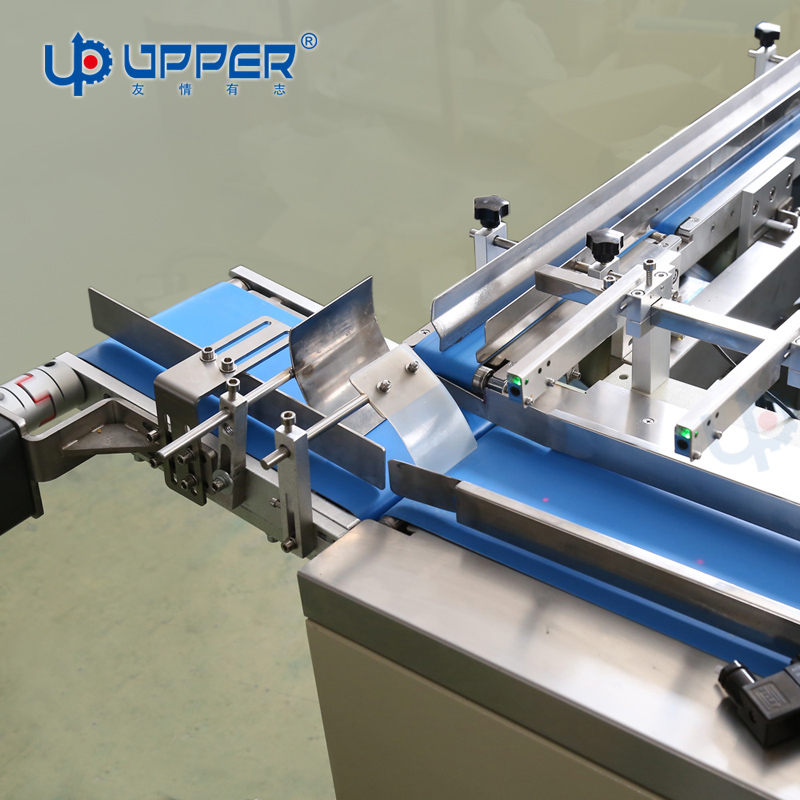

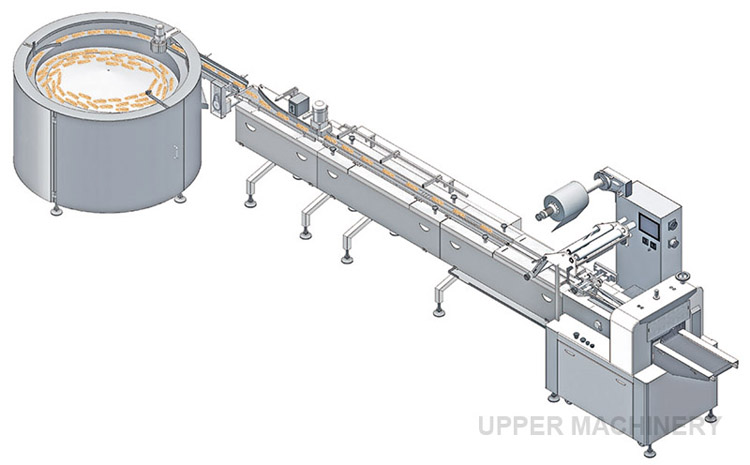

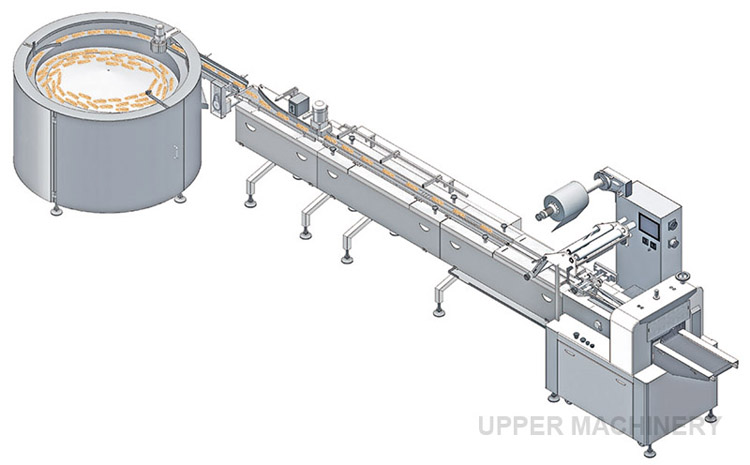

01 The materials are separated by the centrifugal force of the turntable, and the materials are discharged one by one, and the materials are sent to the packaging machine for packaging through the tail rack.

02 For this line is suitable to packing the products like cookies ,biscuit,such bakery products , or the commodity products like the mark pen ,PVC pie such regulaly shape products.

03 Main control circuit adopts developed by our company PLC, color touch screen display, inverter control, perfect interface between operator and machine. That make operation and adjustment easily.

04 The packing speed and the length of the bag are controlled by the double frequency converter. Step-less variable speed, wide adjustment range, can be a perfect match with the production line of the former process.

05 High sensitive electric eye is the function of automatic tracking bags length accurately, no manual adjustment after setting.

We Offer Two Kinds of Biscuit Packing Machines:

—

● Automatic Biscuit Packing Machine. (Directly connect the production machine.)

● Semi-auto Biscuit Flow Wrapper Machine. (Manually feeding the products into the packing machine.)

Automatic Biscuit Packing Machine Types:

—

● Cookies Biscuit Packing Machine

● French Bread Biscuit Packing Machine

● Egg Roll Biscuit Packing Machine

● Double-layer Biscuit Packing Machine

● Wafer Biscuit Packing Machine

● Waffle Biscuit Packing Machine

● Biscuit in Tray Packing Machine

● Biscuit Carton Box Packing Machine

● Customized Three Packing ( individually packaged, big bag packing, carton packing.)

Customized Automatic Biscuit Packaging Machinery, Including:

—

For examples:

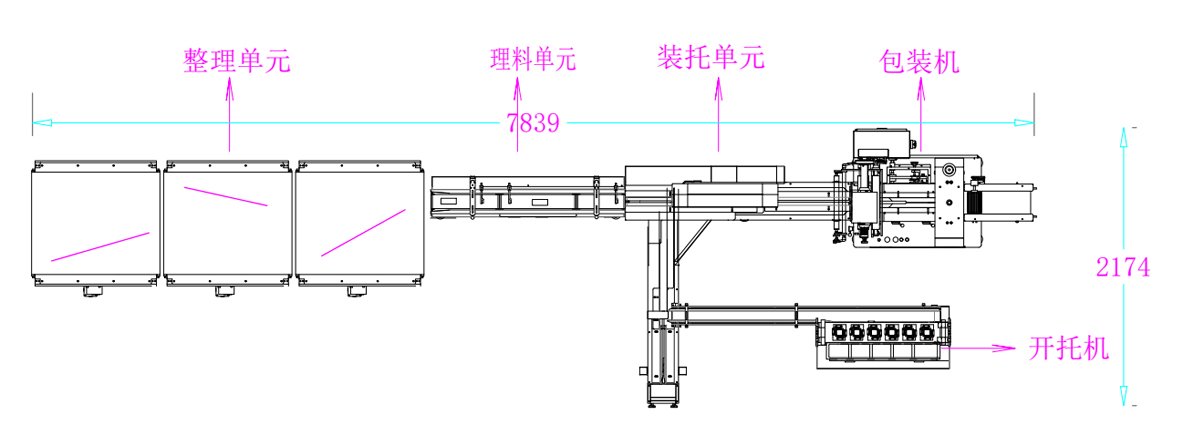

● Biscuit in Tray Packing

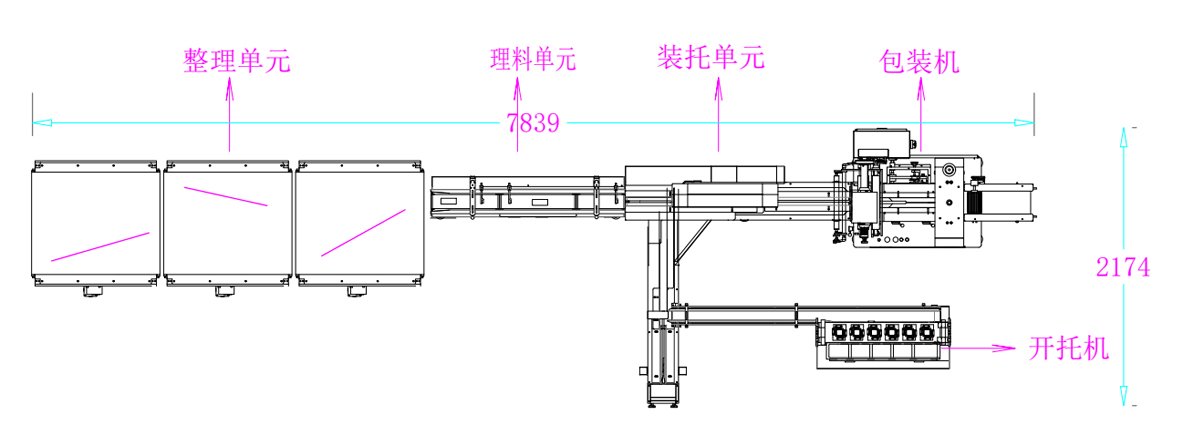

The total line includes the tray filling machine + automatic feeding sorting machine+ pillow packing machine.

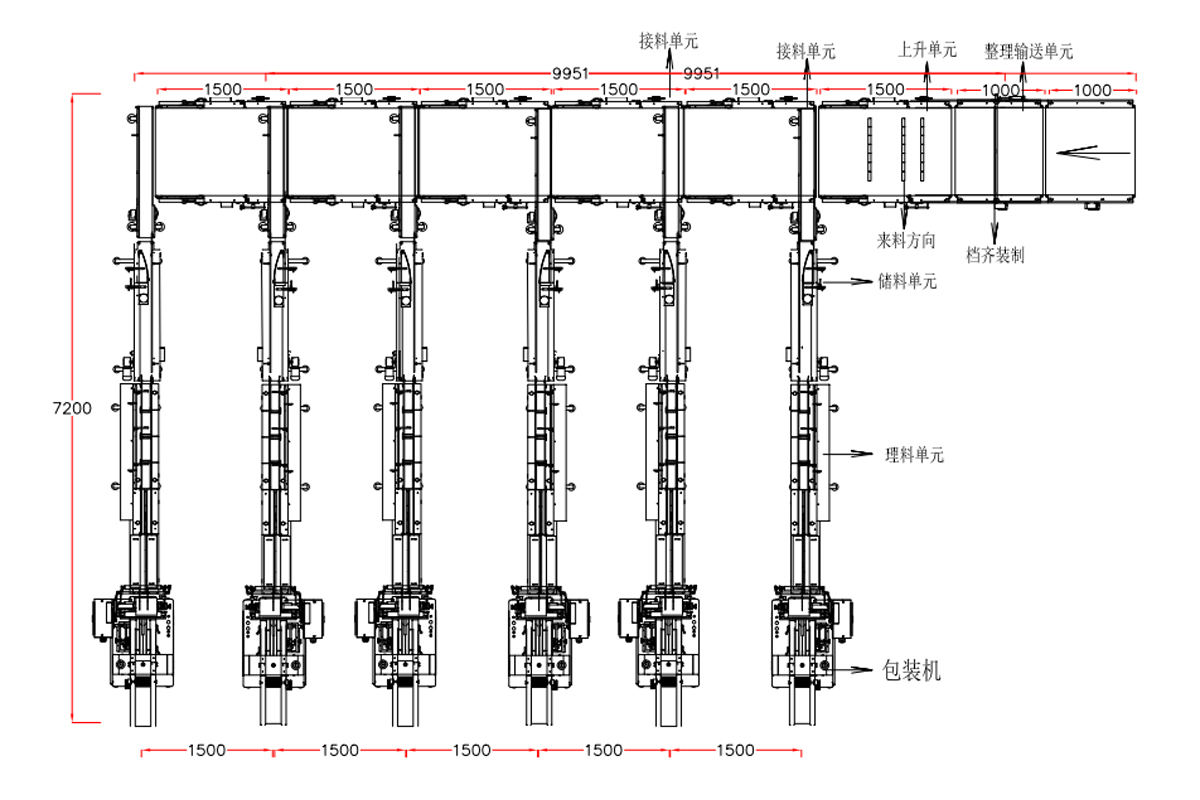

● Biscuit into Double Layer Packing

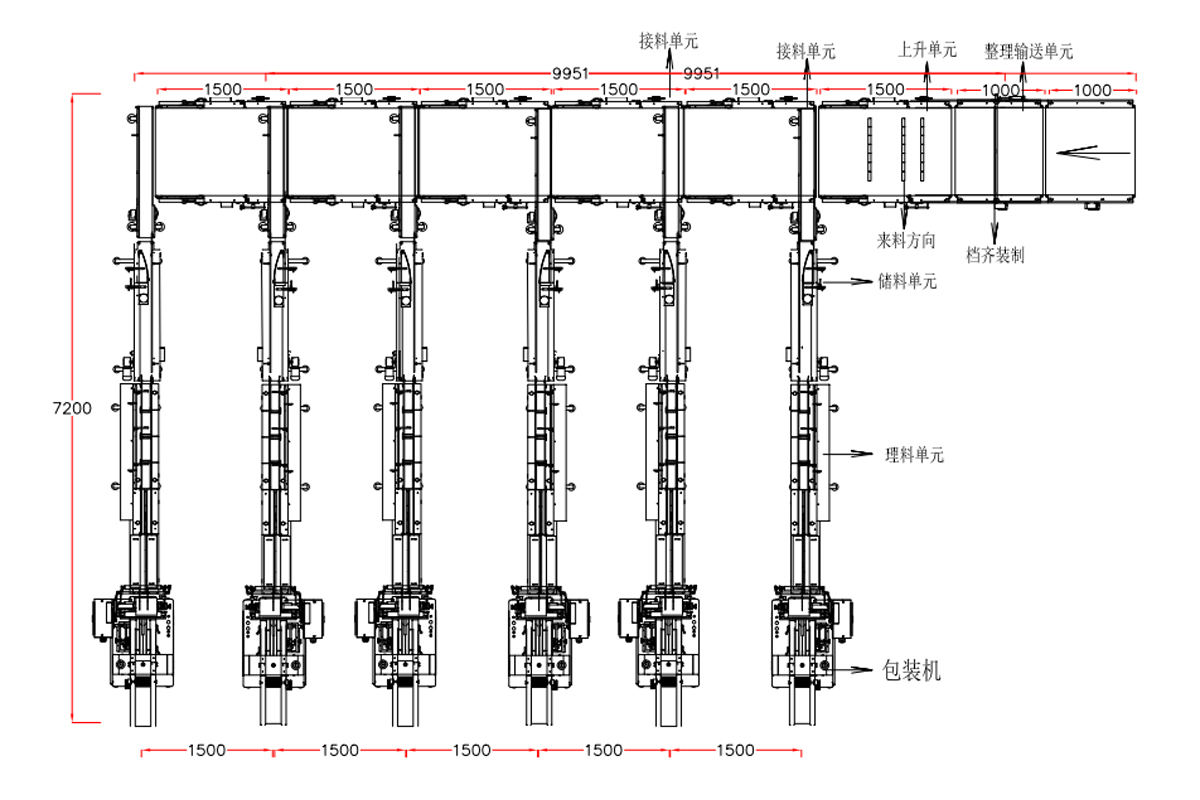

The automatic feeding sorting machine + double-channel conveyor+ horizontal packing machine.

● Biscuit into Carton Box Packing

The total line includes the automatic feeding sorting machine + automatic collecting machine(two lines, two layers, into the carton box)+ conveyor+ carton box packing machine.

● The extra machine is the reciprocating multi-packing machine if you need two packing before the carton box packing.

● Biscuit is a long and round shape. The total line includes the rotating turntable + automatic feeding sorting conveyor + horizontal packing machine.

Biscuit Packing Material

—

● Polyester, cast polypropylene, oriented polypropylene, cellulose, aluminum, etc.

Should You Choose the Frequency Changer or Servo Motor Biscuit Packing Machine?

—

Difference | Double Frequency Conversion Packing Machine | Servo Motor Packing Machine |

Power | Two ordinary motors drive horizontal sealing and feeding, and the other drive vertical sealing. | Horizontal sealing, vertical sealing, and feeding are all controlled by independent motors. The three axes can be divided into one servo motor, two ordinary motors, two servo motors, one ordinary motor, or three servo motors. |

Mechanical Structure | Adjust the cam structure of the knife speed, feed adjustment differential mechanism, feed and cutter power distribution mechanism, and other structures. | Directly driven by motor power. The three-axis structure is simple, reducing mechanical structure transmission and reducing noise. Easy maintenance, less friction, and long life. |

Speed Adjustment of the Horizontal Sealing Cutter | The cam structure is used to manually adjust the speed of the cutter and move the film synchronously. | No adjustment is required, and a motion controller is used to track and synchronize automatically. |

Material Position Adjustment | Manual Adjustment with Differential Mechanism | Enter the digital adjustment on the touch screen, or press "Feeding and Paper Linkage" and other materials to the appropriate position, then press "Set as Feeding Offset". Save material adjustment time. |

Anti-cutting Function | When the material is cut, the whole machine stops working. Need manual readjustment. | When the material is cut, the cutter's work is suspended, and the feeding and longitudinal sealing continue to work. When there is no cutting situation, the packaging machine automatically works normally. Reduce downtime and increase production efficiency. |

When the Anti-cutting Function Is Not Installed | When cutting hard objects, damage the cutter. | When cutting hard objects, the servo alarms and the whole machine stop working to protect the cutter fully. |

Anti-aircraft Bag Function | Non | When there is an empty package in the feeding, the vertical sealing and horizontal sealing will be suspended, and the work will continue when there is material. Reduce the waste of packaging film. |

Replacement Material Packaging Length | To replace products with large differences in material length, mechanical parts need to be changed and the operation complicated. | When changing the length of the material, the operation is simple, just input the relative parameters on the touch screen. |

Recipe Function | Non | The parameter settings of the array packaging products can be saved, and the normal production can be achieved by switching directly without re-adjusting the machinery. Save the adjustment time of replacing packaged products. |

Requirements for Operators | A more extended transition period of mechanical familiarization is required, and specific technical requirements are necessary. | Intelligent and humanized parameter settings can be used skillfully in a short time. |

Should You Choose the Automatic or Semi-auto Biscuit Packing Machine?

—

Semi-auto Biscuit Horizontal Packaging Machine | Automatic Biscuit Packaging Machine |

Small production | Big production capacity |

Manually feeding the biscuit | Directly connect the biscuit production machine |

Handling, a certain degree of wear and tear | Hand contact and handling effectively reduce wear |

Operation technicians need familiar packaging machinery foundation | Intelligent operation, few manual operations, saving time |

Lower machine cost | Valuable price |

The footprint of the machine is relatively small | Customized footprint |

The Optional Device:

—

● Inflatable Device

● Special Sealing Method

● All Stainless Steel

● Coding Machine

● Exhaust Device

To Ensure We Recommend You the Suitable Machine Model, Please Kindly Send Us Your Requirements:

—

● Product incoming methods: such as neat incoming materials, manual pours, scattered incoming materials, etc. (preferably with video.)

● Product Characteristics: fragile, regular, soft, sticky, etc. (It is best if you can provide samples)

● Packing Method: such as one pack; two packs up and down, etc. (preferably with pictures)

● Production Capacity: how many products per minute?

● Packing Speed: What is your requirement for packing speed?

● Size of the Venue: Do you have requirements for the size of the venue?

Please Check Some of Our Packing Solutions Projects as Below:

—

Applications:

Roll biscuits, cakes, bread, muffins, moon cakes, masks, hardware parts, etc.