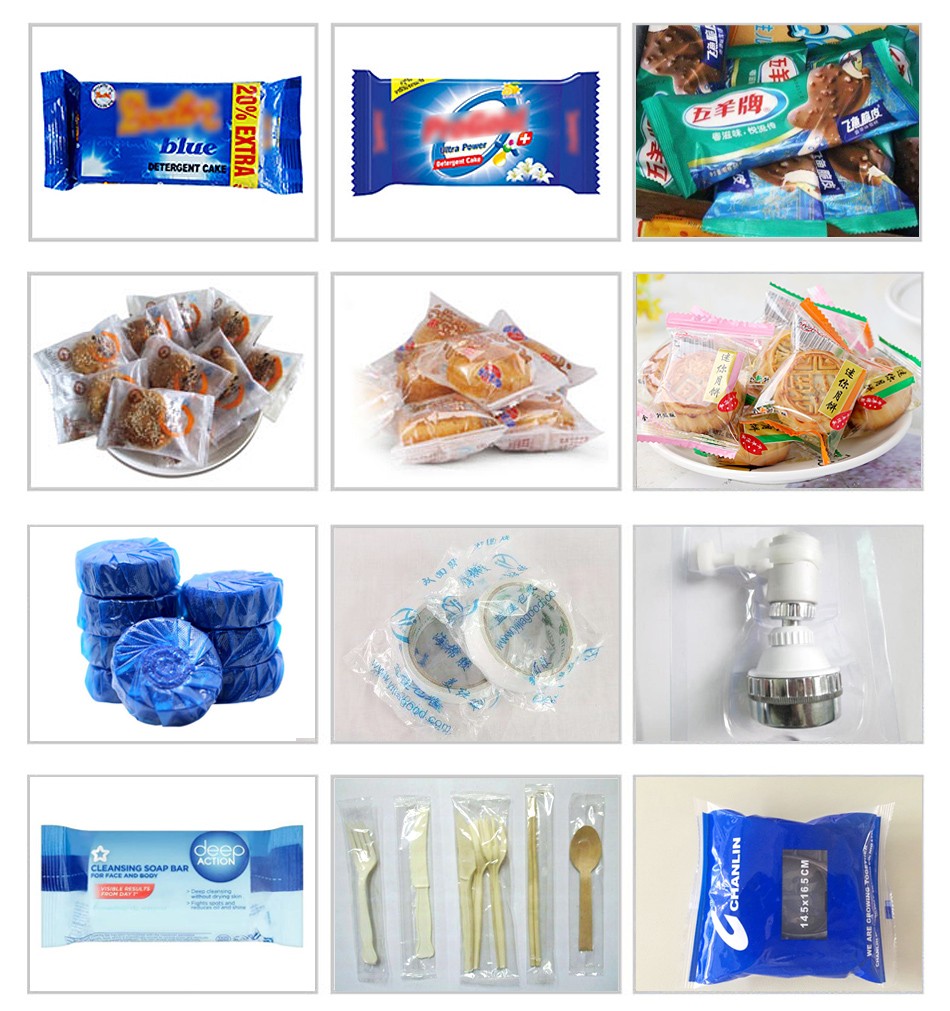

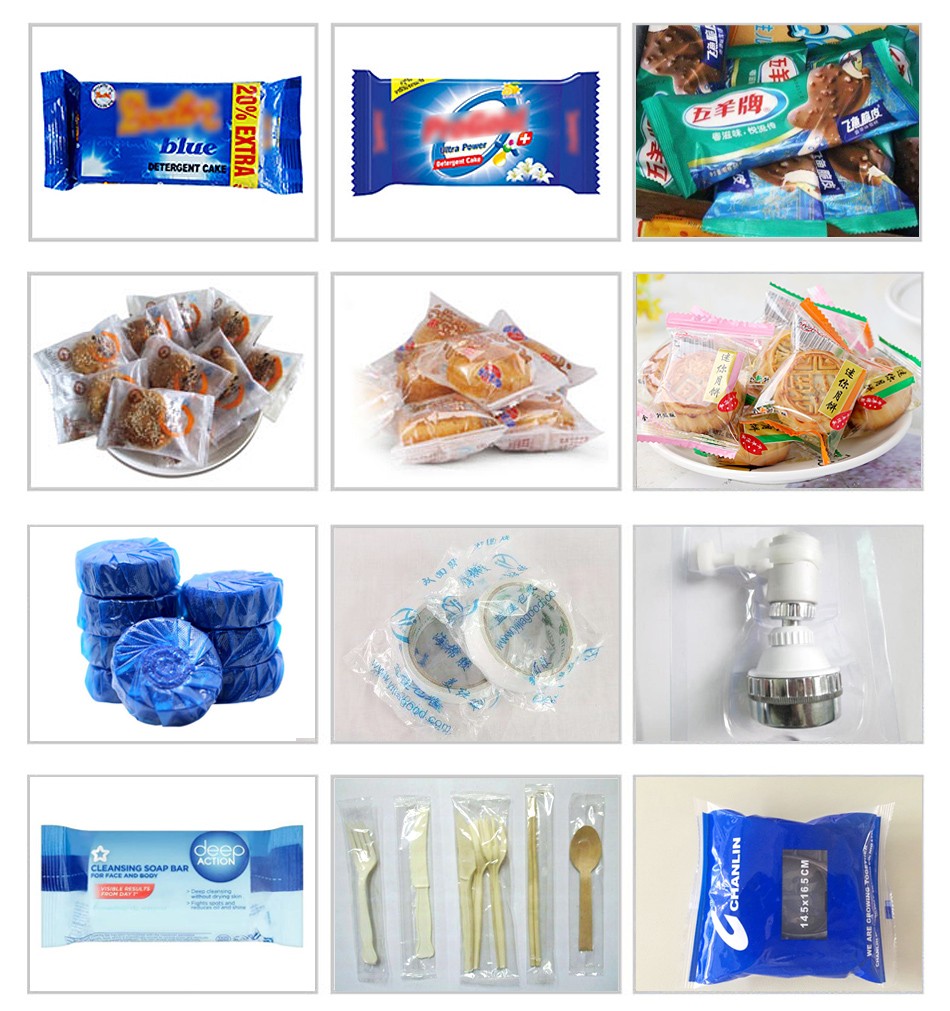

The machine is suitable for all kinds of solid and regular material, such as biscuits, cakes, bread, Hamburgers, moon cakes,

Egg rolls, fruit pie, instant noodles, medicine, daily products, hardware, and plastic toy.

Features:

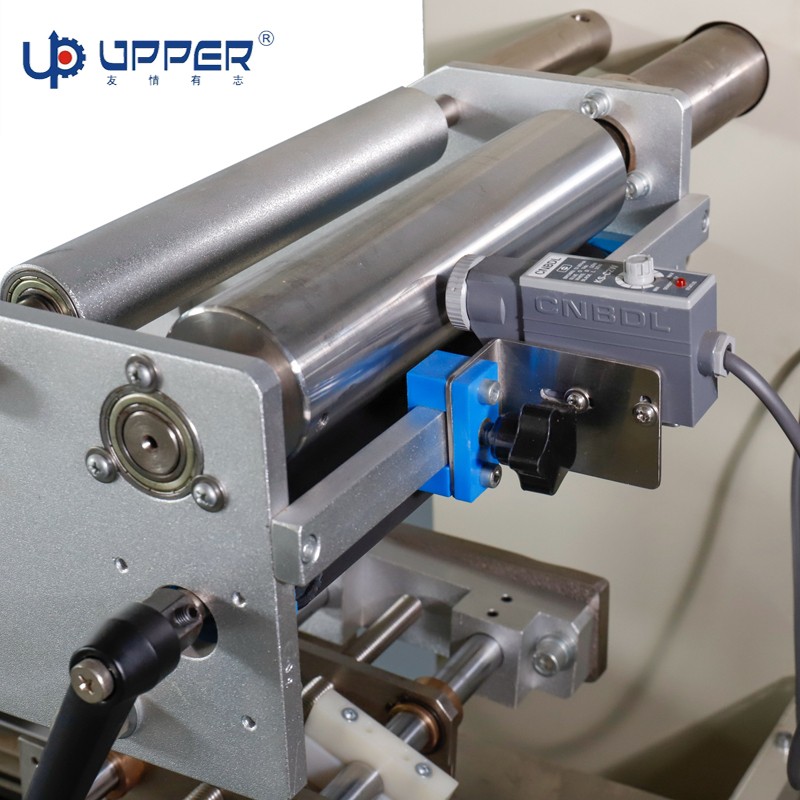

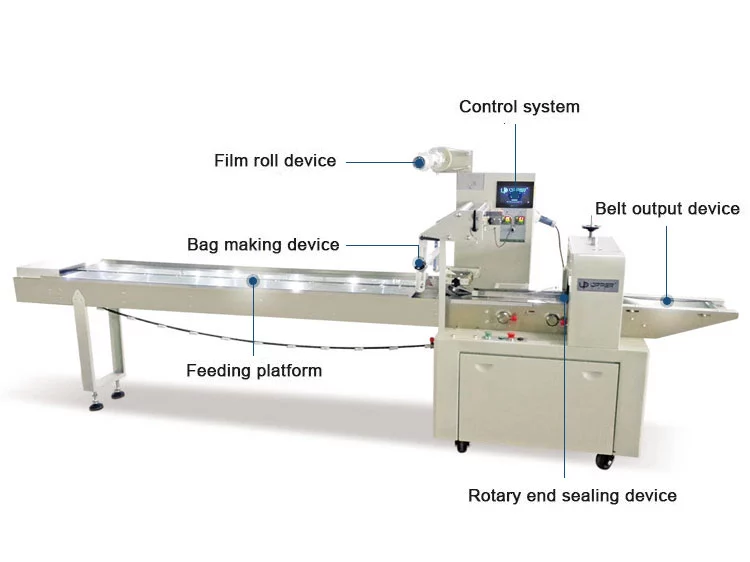

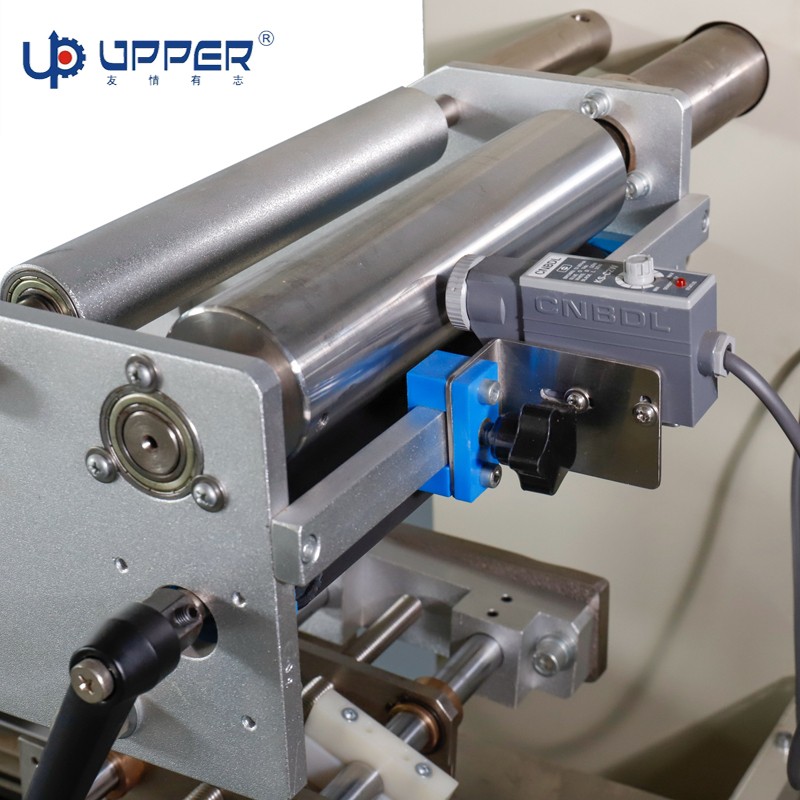

1. Film drawing up system controlled by frequency motor or servo motor.

2. Automatic film rectifying deviation function.

3. Various alarm systems to reduce waste.

4. It can complete feeding, measuring, filling, sealing, date printing, charging (exhausting), counting, and finished product delivery when it equips with feeding and measuring equipment.

5. The way of bag making: the machine can make pillow-type bags.

6. Colored touch screen, perfect interface between operator and machine; big colored touch screen, digital temperature controller system, easy to set parameters and operate for changing different size products; world brand high sensitivity photocell tracking system, to control products position exactly.

7. Electrical professional design, easy control, and more stable.

Applications:

The machine is suitable for all kinds of solid and regular material, such as biscuits, cakes, bread, Hamburgers, moon cakes, egg rolls, fruit pie, instant noodles, medicine, daily products, hardware, and plastic toy.

Specifications: