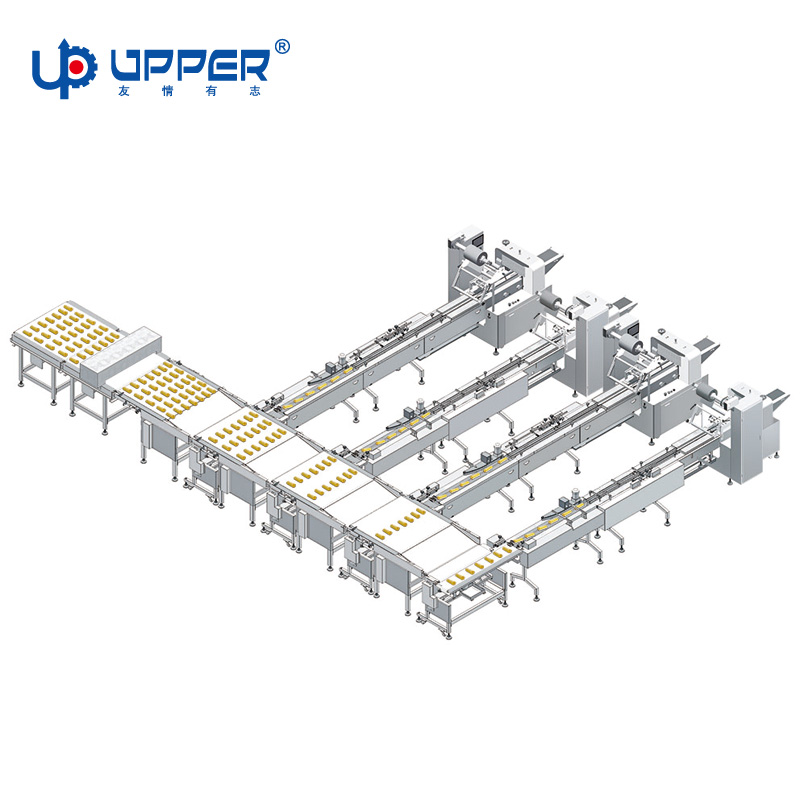

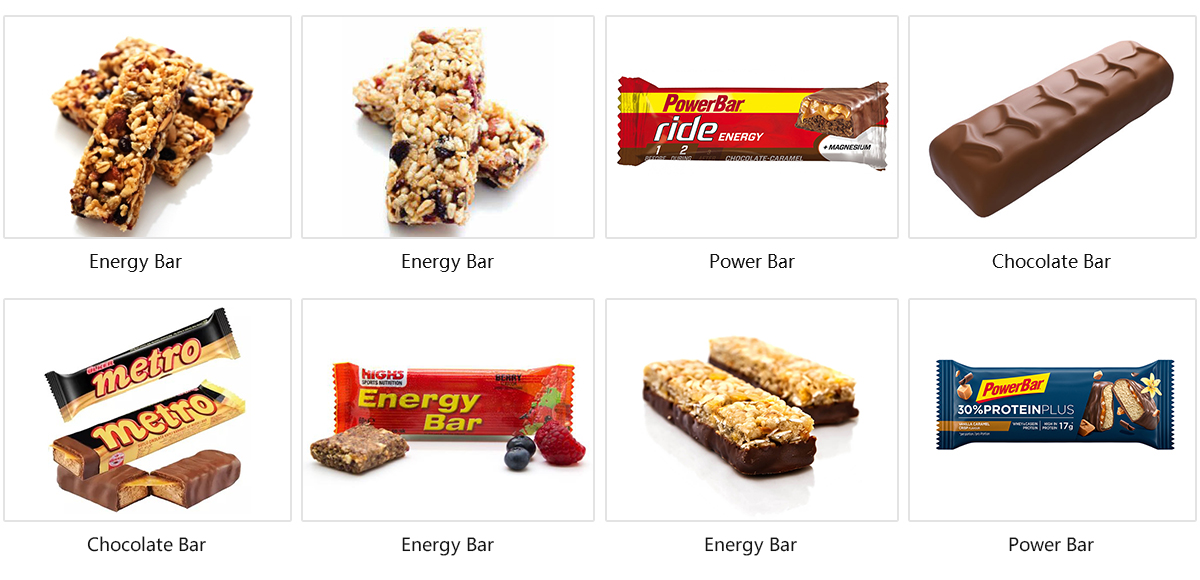

Energy Bar Packaging Machine

Introduction to Our Energy Bar Packaging Machine

—

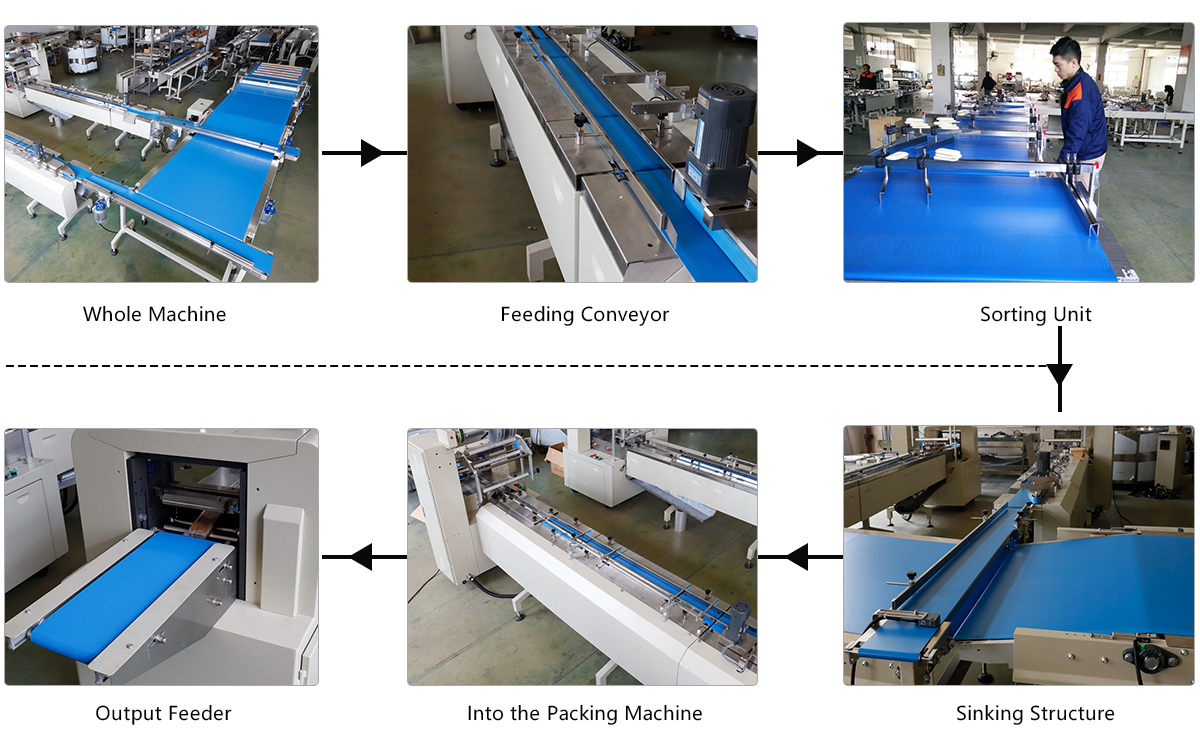

● This packaging line consists of three different systems: food packaging, material management and packaging. Each has a corresponding speed adjustment and product size information input to choose the most suitable solutions accordingly.

● The product input structure is specifically designed to protect the integrity of the entire chocolate bar effectively, ensuring consistency throughout every product for your customers.

● This system’s unique method of rising and sinking is suitable for chocolate bars with numerous different characteristics and meets the different feed speed requirements of numerous product types.

● The high-precision and sensitive SICK electric eye tracking system ensures accurate material position control during production.

● This machine integrates a premium stainless steel structure and humanized design, making installation, disassembly, and maintenance simple and fast.

Advantages

—

【Excellent Price】

● Supply by our factory directly.

【Packaging Line Customization Is Available】

● Our highly experienced engineer team is always here for you, no matter what requirements you might have. (We have over 20 years of experience in the packing machine industry)

【Quality Assurance】

● All of our products adhere to CE, ISO, Patent, and Quality Assurance Certifications. We can also deliver a high-tech enterprise certificate.

【Fast Delivery & Professional After-sales Service】

●Over 50 dedicated workers contribute to our production team.

【Time-saving, Cost-saving, High Efficiency】

● You can readily connect this machine with your current production line directly. Fully automatic feeding-alignment-orienting-distributing-packing is provided all in a single production line.

【Excellent Machine Stability】

● Adopt multi-variable frequency speed control and servo drive control.

【Easy To Operate】

● Users can readily implement a colored touch screen for easy operation and adjustment of the device. In addition, fault displays and data storage functions operate easily even when changing between products with different sizes as standard.

【Production Guarantee】

● Every piece of equipment that we provide is designed based on your unique product characteristics, which ensures that the products always fit within the machine itself. When the product is experiencing a fail scenario, you can readily remove any unacceptable products without stopping the machine from running.

Why Does my Business Need an Automatic Energy Bar Packaging Machine?

—

● Increase your packing capacity.

● Enhance your brand’s efficiency in packing chocolate bars and candy bars.

● Reduce your time packing chocolate bars and candy bars using an automated packing system.

● Reduce the number of employees in the production line by automatically automating most basic functions.

This excellent machine will boost your energy bar production and maximize profit margins in the long run.

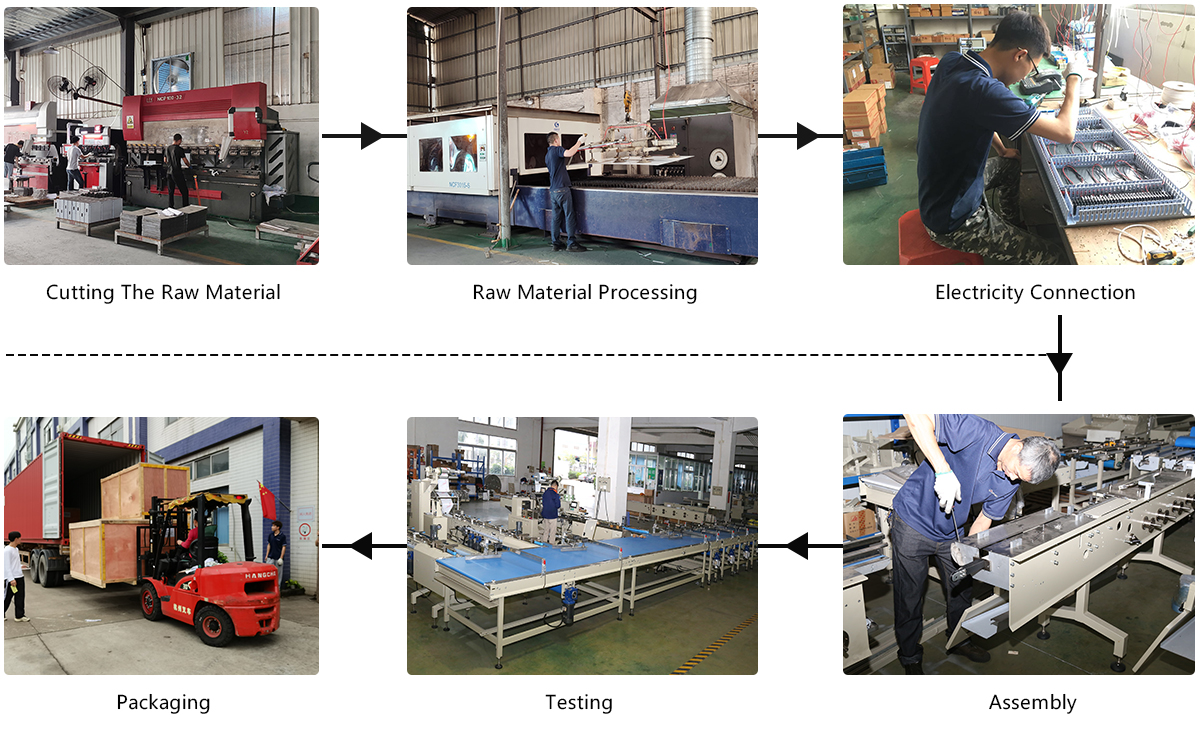

How to Adjust the Energy Bar Packaging Machine?

—

● Ensure that any raw materials are always kept in plentiful supply to ensure that the machine does not stop running.

● Always check that you have entered the correct packing parameters in the PLC control system to allow for smooth operations.

● Confirm whether the electrical wires are loose and check whether they are well connected.

● Regular machine cleaning and maintenance will keep the system in perfect working condition at all times.

Our Fully Automatic Energy Bar Packing Line Primarily Includes:

—

● Automatic feed / input conveyor

● Power baffle

● Steering structure

● Energy bar horizontal flow packing machine

● Energy bar carton box machine

Choose the Automatic Or Semi-auto Energy Bar Packing Machine?

—

Semi-auto energy bar packaging | Automatic energy bar packaging |

Small-scale production |

Large production capacity |

Manually feeding the energy bar

|

Directly connect the energy bar production machine

|

Handling can deliver a certain degree of wear and tear | Hands-free contact and handling effectively limit the level of wear and tear on the machine |

All operation technicians using the machine must be familiar with packaging machinery foundations

|

Intelligent operation with very few manual operations, saving time for your business

|

Lower machine cost | Valuable price |

The footprint of the machine is relatively small | Customized footprint |

There Are Two Ways that our Automatic Energy Bar Packing Machine Can Work:

—

● Automatic power baffle energy bar packing line (due to the short bar length and high-speed requirements)

● Automatic ascending and sinking energy bar feeding packing machine (due to being contact-free with materials’ packing requirements)

Both Energy Bar Packing Machines Have Dual Frequency Motor & Servo Motor Driven Conversion.

—

Please Check Their Differences As Below:

Differences |

Double Frequency Conversion Packing Machine

|

Servo Motor Packing Machine

|

Power |

Two ordinary motors drive horizontal sealing and feeding, and the other drives vertical sealing.

|

Horizontal sealing, vertical sealing, and feeding are all controlled by independent motors.

The three axes can be divided into one servo motor, two ordinary motors, two servo motors, one ordinary motor, or three servo motors.

|

Mechanical Structure |

Adjust the cam structure of the knife speed, feed adjustment differential mechanisms, feed and cutter power distribution mechanisms, and other structures.

|

Directly driven by motor power.

The three-axis structure is simple, reducing mechanical structure transmission and reducing noise. Easy maintenance, reduced friction, and a long lifespan.

|

Speed Adjustment of the Horizontal Sealing Cutter

|

The cam structure is used to manually adjust the speed of the cutter and move the film synchronously.

|

No adjustment is required, and a motion controller is used to track and synchronize actions automatically.

|

Material Position Adjustment |

Manual adjustment with differential mechanism

|

Enter digital adjustment on the touch screen, or press “Feeding and Paper Linkage” and other materials to the appropriate position, then press “Set as Feeding Offset.”

Save material adjustments over time.

|

Anti-cutting Function |

When the material is cut, the whole machine stops working, and may need manual readjustment.

|

When the material is cut, the cutter’s work is suspended, and the feeding and longitudinal sealing continue to work. When there is no cutting situation, the packaging machine automatically works normally.

Reduce downtime and increase production efficiency.

|

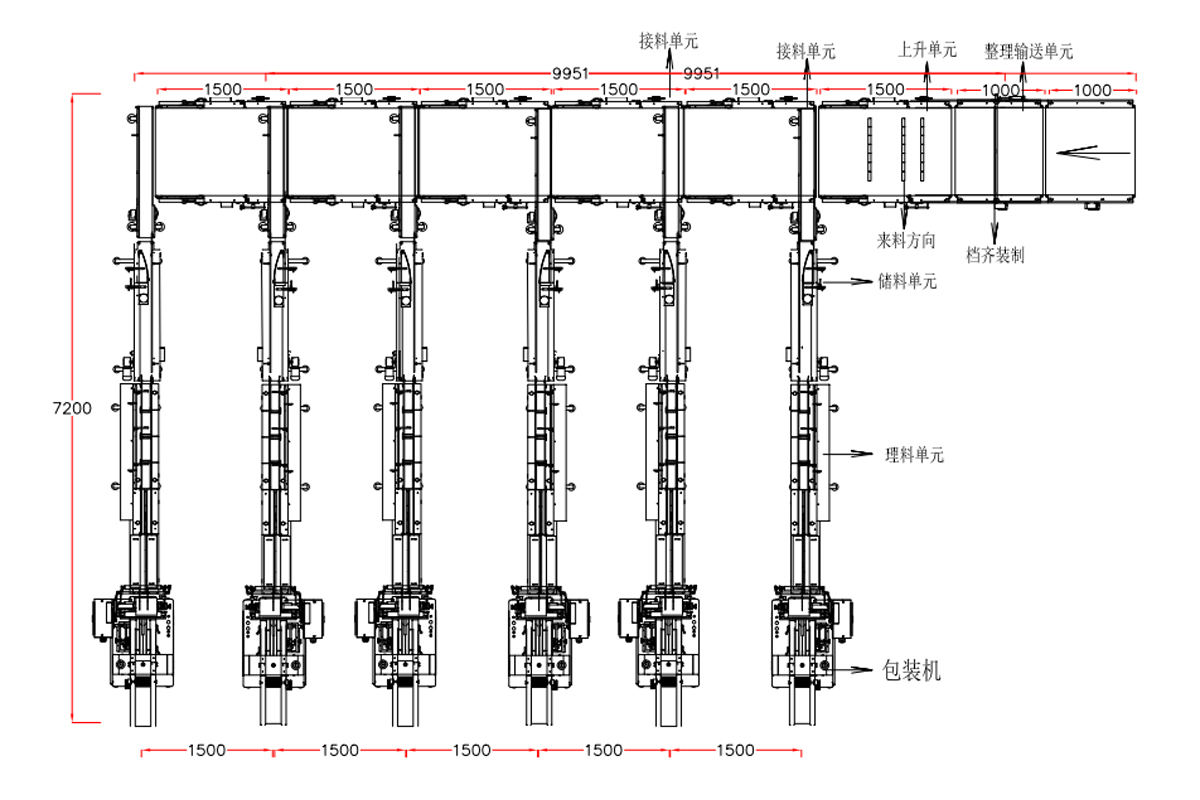

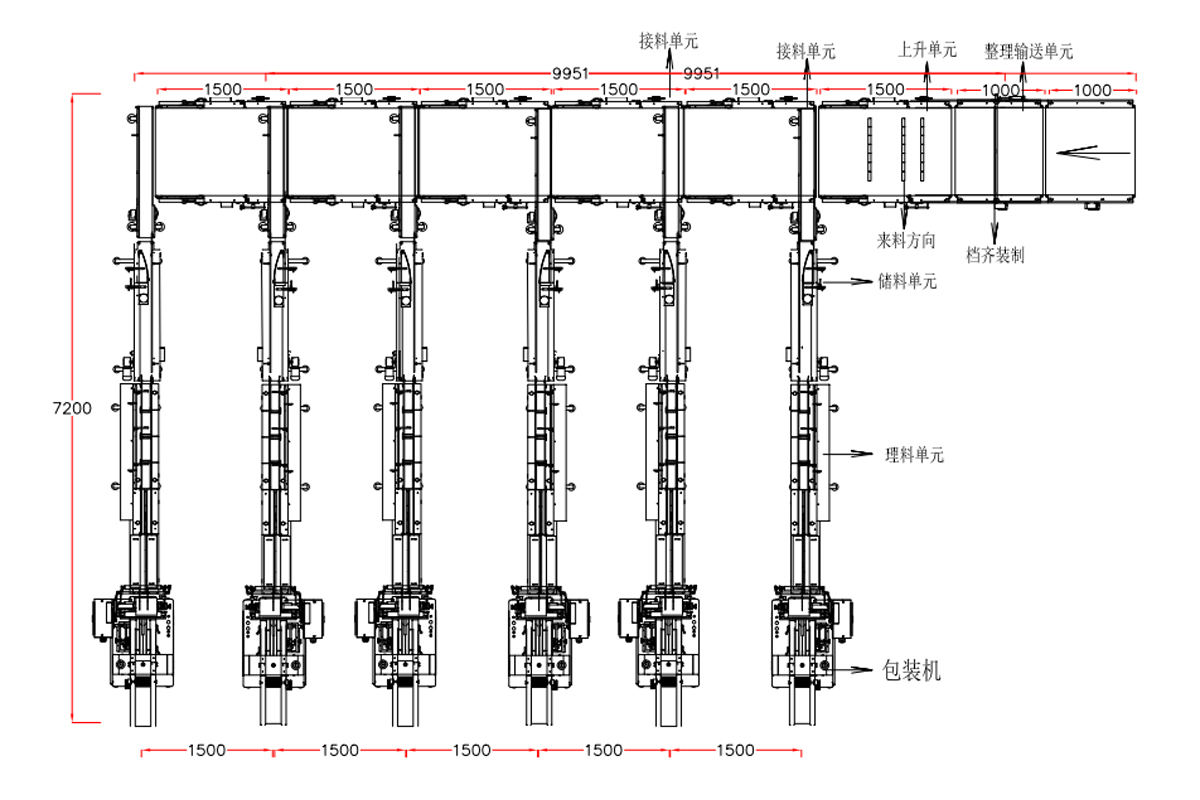

Check Out Some of Our Past Candy Bars/Chocolate Bars Packing Layout Projects:

—

Please Send Us Your Requirements, We Will Send You CAD Drawings and Quotations Accordingly.

—

● Product incoming methods: such as neat incoming materials, manual pours, scattered incoming materials, preferably with video.

● Product characteristics: fragile, regular, soft, sticky, etc., best with samples pictures.

● Packing method: one pack, two packs up and down, etc., preferably with pictures.

● Production Capacity: how many products per minute?

● What is the requirement for packing speed?

● Do you have requirements for the size of the venue?

Product Name | Energy Bar Packing Machine |

Product Size |

9000×950×1500mm |

Master Conveyor Belt Width | 600/800/1000/1200mm |

Net Weight | Customized |

Packing Capacity |

50-200 bags/min (per single lane) |

Power Supply | 1ph-220V-50Hz or 3ph-380V-50Hz |

Total Power | Customized |