Label Machine

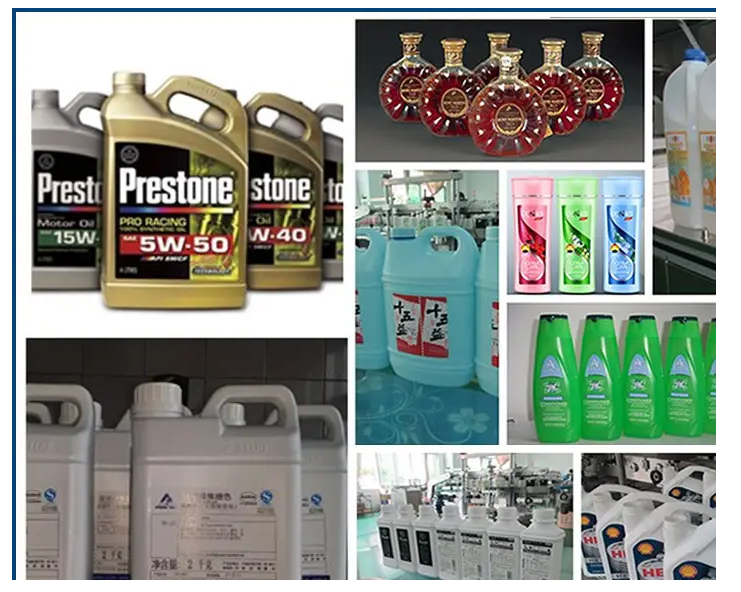

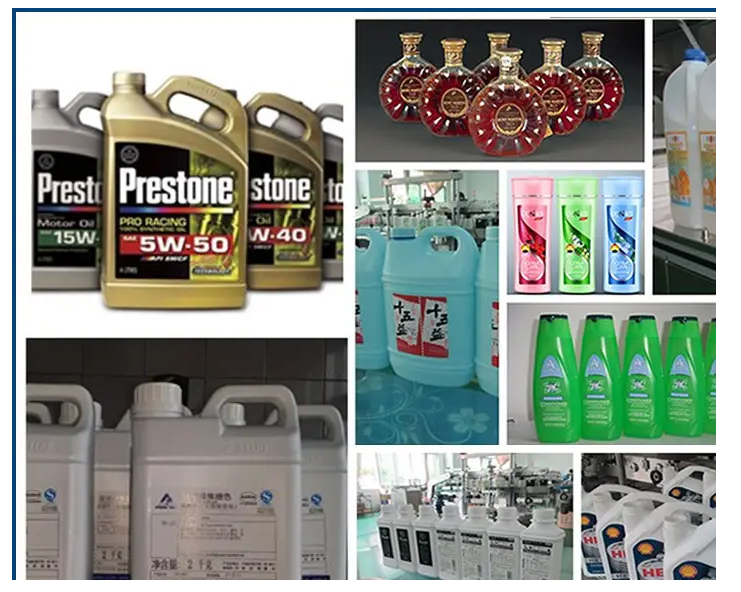

Application

It applies self-adhesive labels onto various round bottles, whether pet bottles, glass bottles, wine bottles, or vials, used in cosmetics, food, toys, daily chemical, electronics, pharmaceutical, plastics, printing, and other industries.

It can select a code printer or inkjet coder to label the head to realize the print product's date, system number, bar code, and other information.

For the trained flavor bags of food, daily consumption, chemical, and medicine, etc.

Widely applied to the production line, such as cap turning machine, induction cap sealer machine, bottle unscrambler, and counting grain machine.

Feactures

◆ The label has a high degree of coincidence. A rectifying mechanism bypasses the label. The label is not deflected. The labeling position is x/y/z, and the inclination is adjustable. The total of eight degrees of freedom is adjustable.

◆ Excellent labeling quality, adopting elastic pressure-coated belt, flat labeling, no wrinkles, and improved packaging quality.

◆ Flexible application, bottle standing labeling, automatic bottle splitting function, can be produced in a single machine or can be connected to the production line.

◆ Intelligent control, automatic photoelectric tracking, with no material and no labeling, no automatic calibration, and automatic label detection to prevent leakage and label waste.

◆ High stability, Panasonic PLC + Panasonic touch screen + Panasonic needle-shaped electric eye + German labor test label electric eye composed of advanced electronic control system, support equipment 7 × 24 hours of operation.

◆ Simple adjustment, labeling speed, conveying speed, and bottle dividing speed can achieve stepless speed regulation and adjust according to need.

Parameters

Labeling range

| L<300mm,H<120mm |

| Labeling speed | 30 bottle/min |

| Labeling accurancy | ±1.5mm |

| Size of main frame | L1900*W800*1450(mm) |

| Working voltage | 220V

|

| Electricity power | 420W |

| Weight | 250KG |

| Packing dimension | 2100(L)*1150(W)*1450(H)mm |