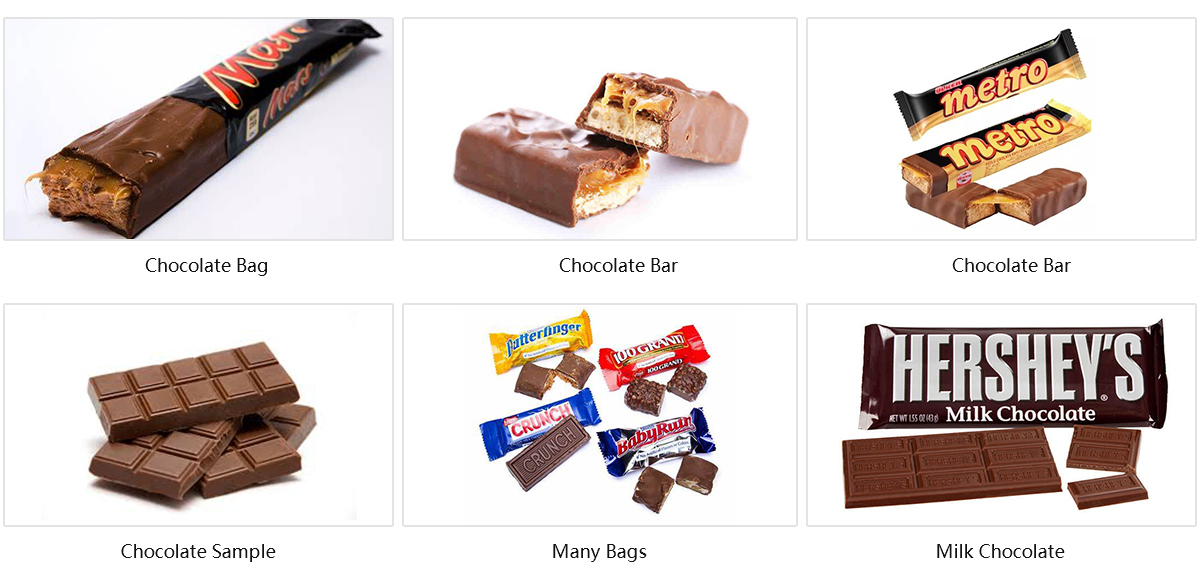

Candy Bar, Chocolate Bar Wrapper Machine

Introducting our Candy Bar, Chocolate Bar Packaging Machine

—

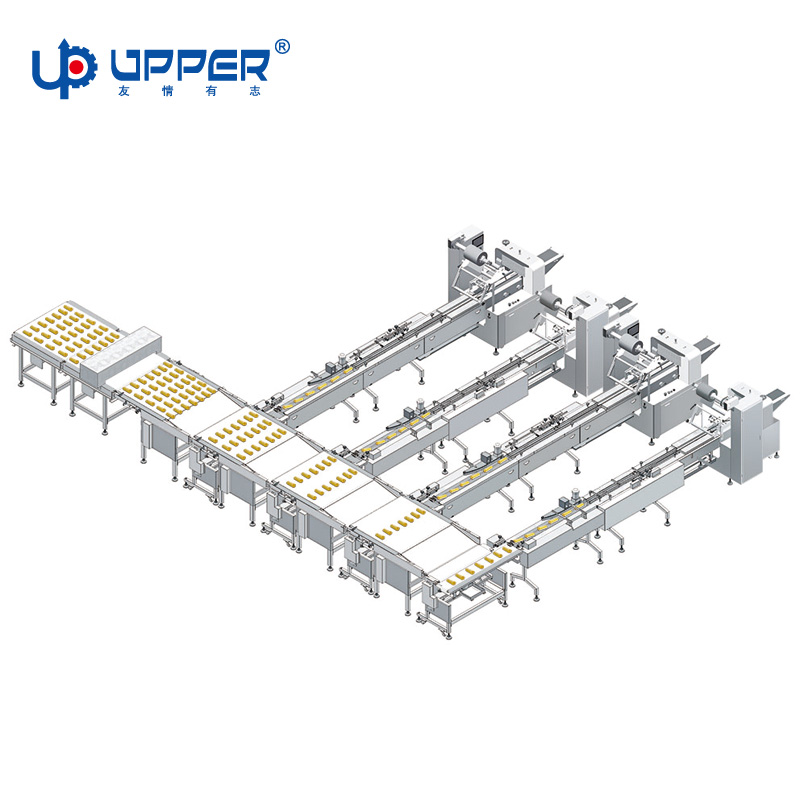

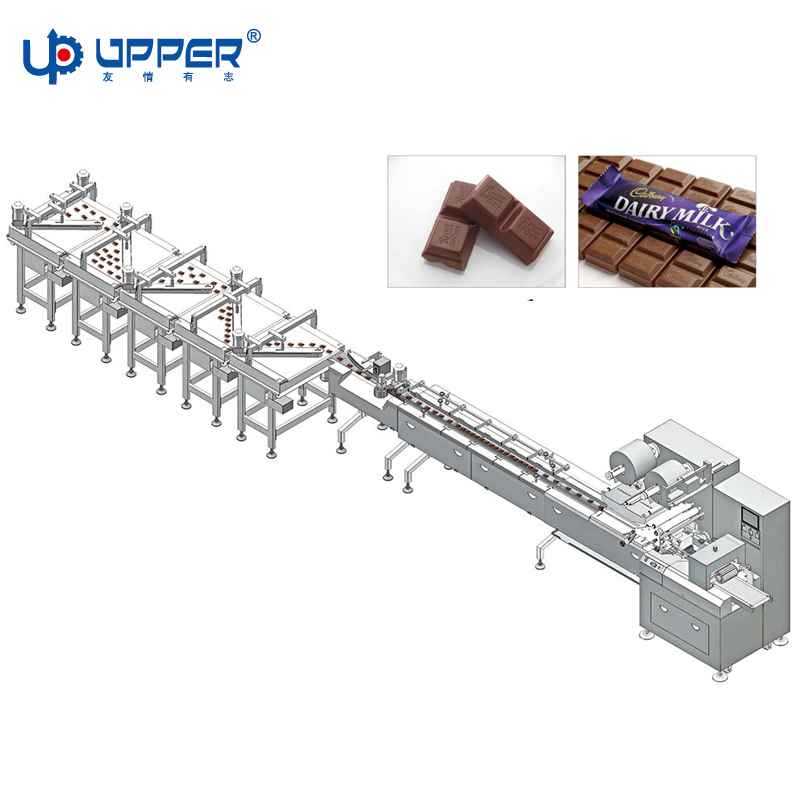

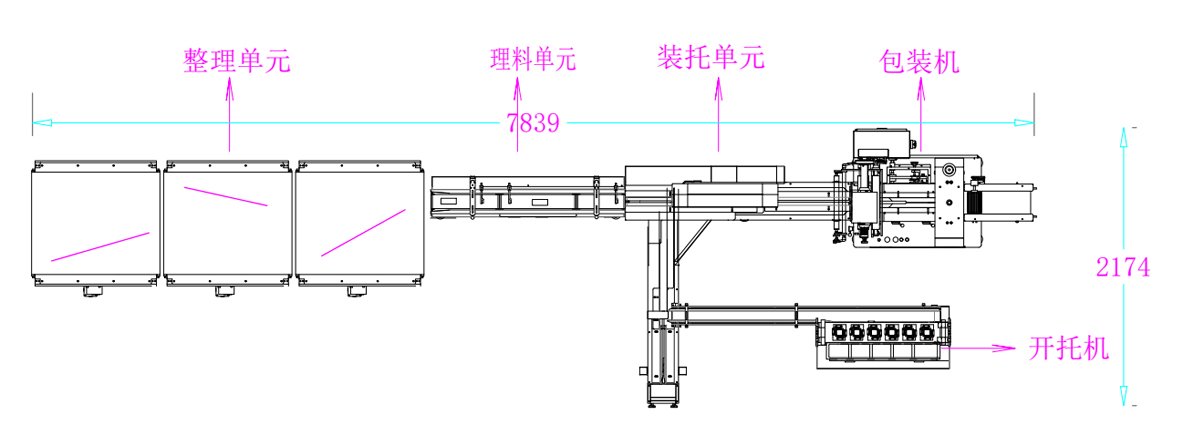

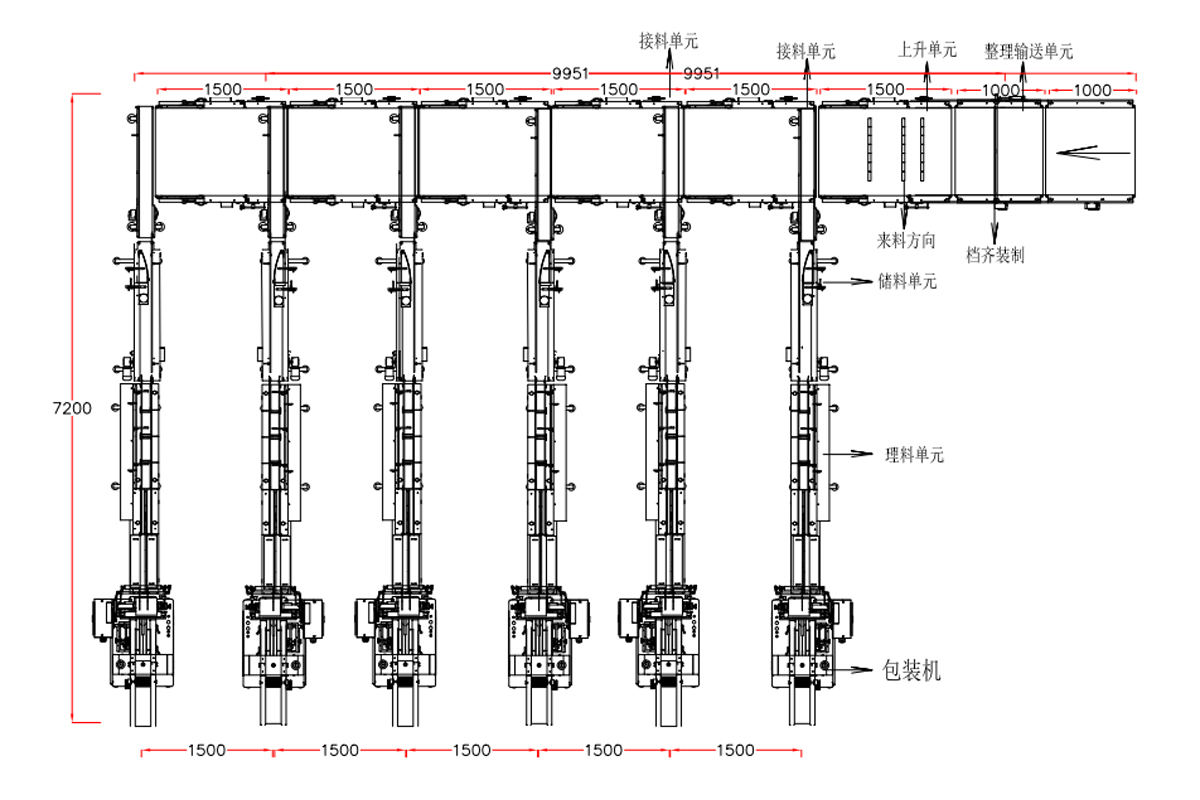

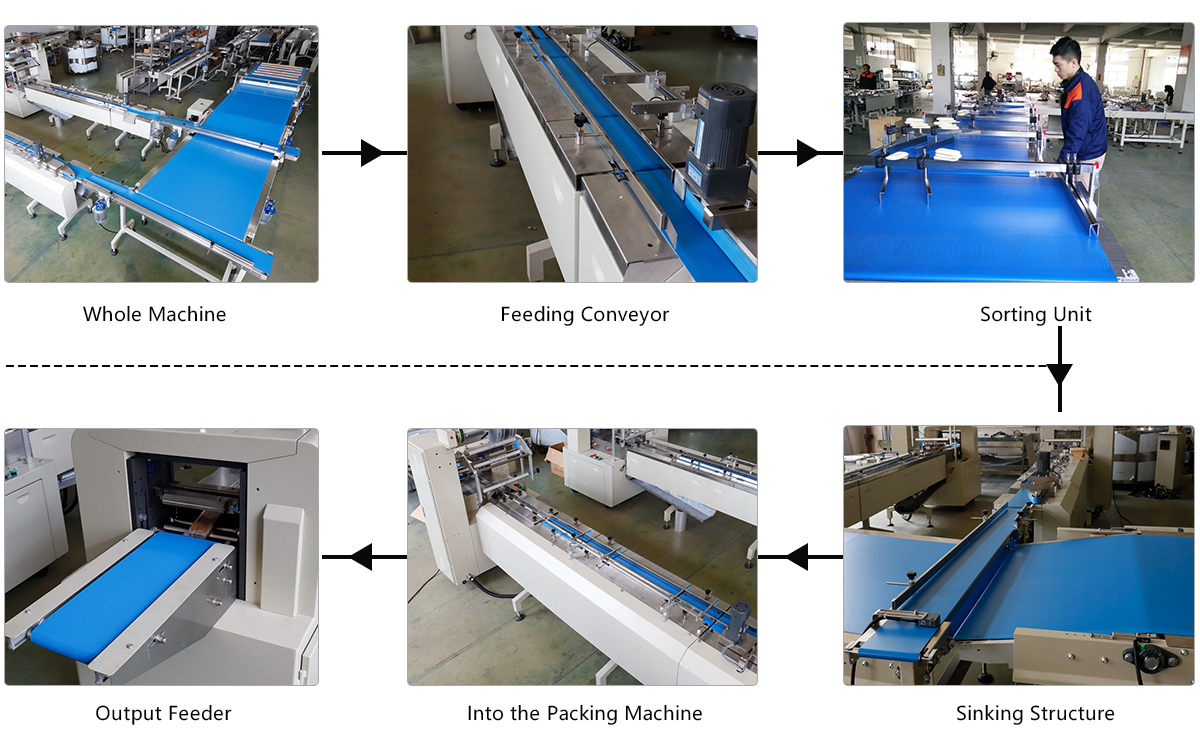

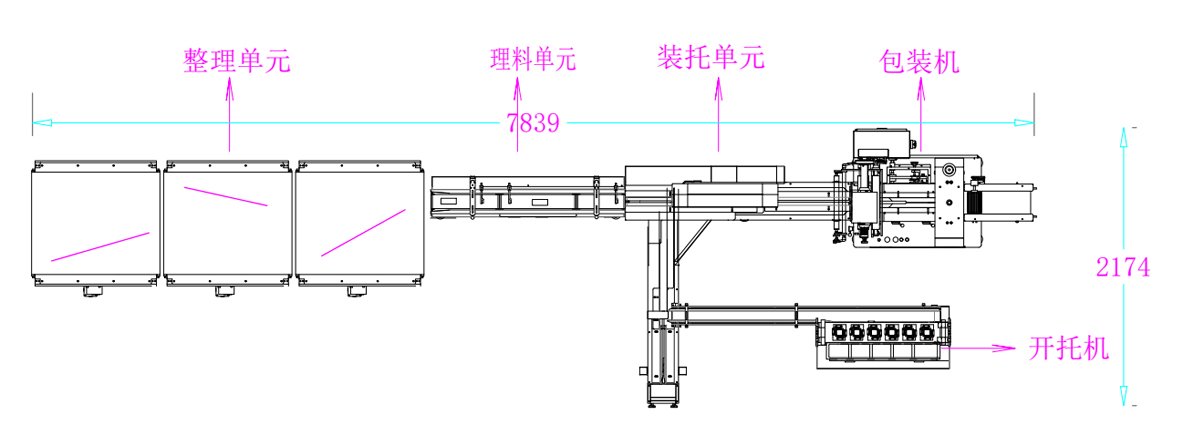

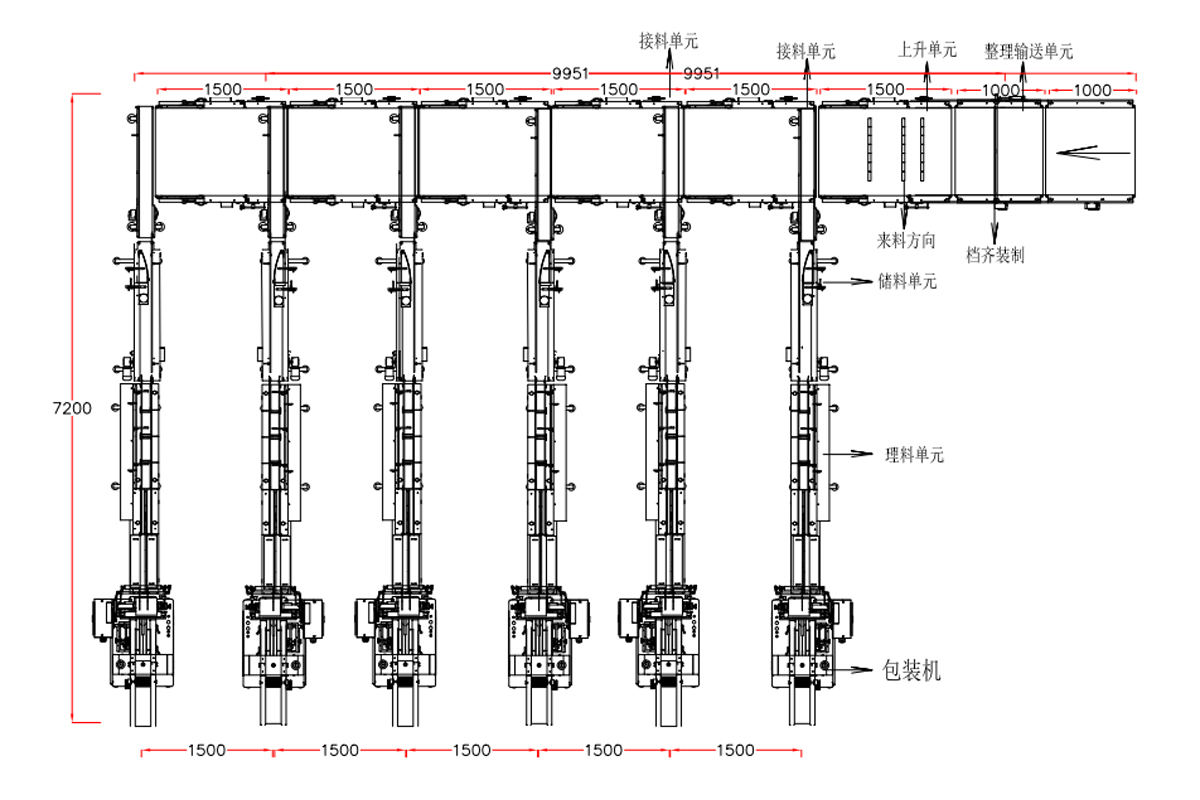

● This packaging line consists of three structures: feed (inputs), material management, and packaging. Each has a corresponding speed adjustment and product size information input.

● The input structure is specially designed to effectively protect every chocolate bar’s integrity and authenticity.

● The method of rising and sinking is suitable for many different chocolate bar characteristics and follows the feeding speed requirements.

● High-precision and sensitive SICK electric eye tracking system ensures accurate material position control throughout the process.

● Stainless steel structure and a humanized design, which makes installation, disassembly, and maintenance simple and fast.

Advantages

—

【Nice Price】

● Supply by factory directly.

【Packaging Line Solutions Customization Is Available】

● Experienced engineer team is always here for you. (over 20 years experience in the packing machine industry)

【Quality Assurance】

● Products with CE, ISO, Patent, Quality Assurance Certifications. High-tech enterprises certificate.

【Fast Delivery & Professional After-sales Service】

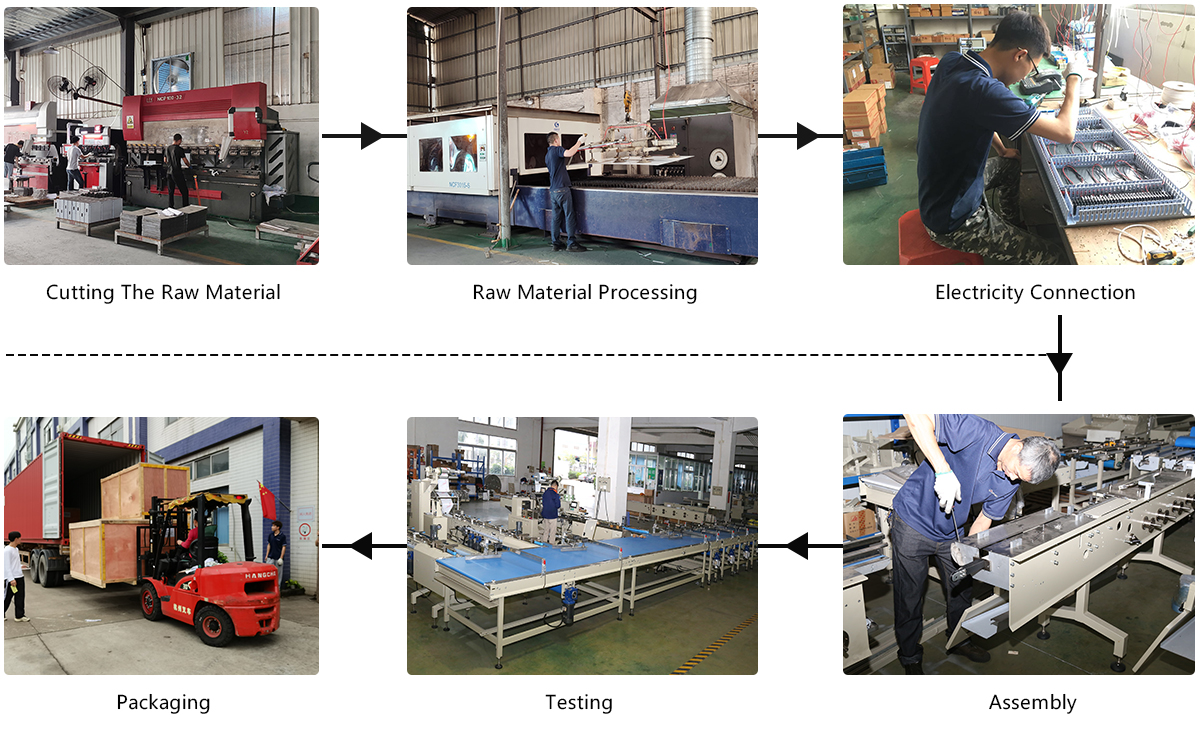

● With more than 50 workers in the production team.

【Time-saving, Cost-saving, High Efficiency】

● This equipment could be connected with the production line directly. Full automatic feeding-alignment-orienting-distributing-packing, all in one line.

【Machines Works Stable】

● Adopt multi-variable frequency speed control, servo drive control.

【Easy To Operate】

● Adopt colored touch screen, easy operation and adjustment, fault display, data storage function, to operate easily for changing different size products.

【Production Guarantee】

● Equipment designed by product characteristics to avoid products extruding. When the product is in fail condition, remove unacceptable one without stopping machines.

Why Do I Need an Automatic Candy Bar/Chocolate Bar Packaging Machine?

—

● Increase your business’s packing capacity.

● Increase the efficiency of packing chocolate bars and candy bars.

● Reduce the amount of time spent packing chocolate bars and candy bars using an automated packing machine.

● Reduce the number of employees in your production line (most functions are automatic).

The machine will boost your chocolate production and maximize profits in the long run.

How to Adjust the Candy Bar/Chocolate Bar Packaging Machine?

—

● Ensure that the raw materials are in plenty of supply to ensure that the machine does not stop.

● Ensure that you enter the correct packing parameters in the PLC control system to allow smooth operations.

● Confirm whether the electrical wires are loose, and check whether they are well connected.

● Regular cleaning and maintenance of the machine will keep the machine in perfect working conditions at all times.

Our Full Automatic Candy Bar/Chocolate Bar Packing Line Primarily Includes:

—

● Automatic feeding conveyor

● Power baffle

● Steering structure

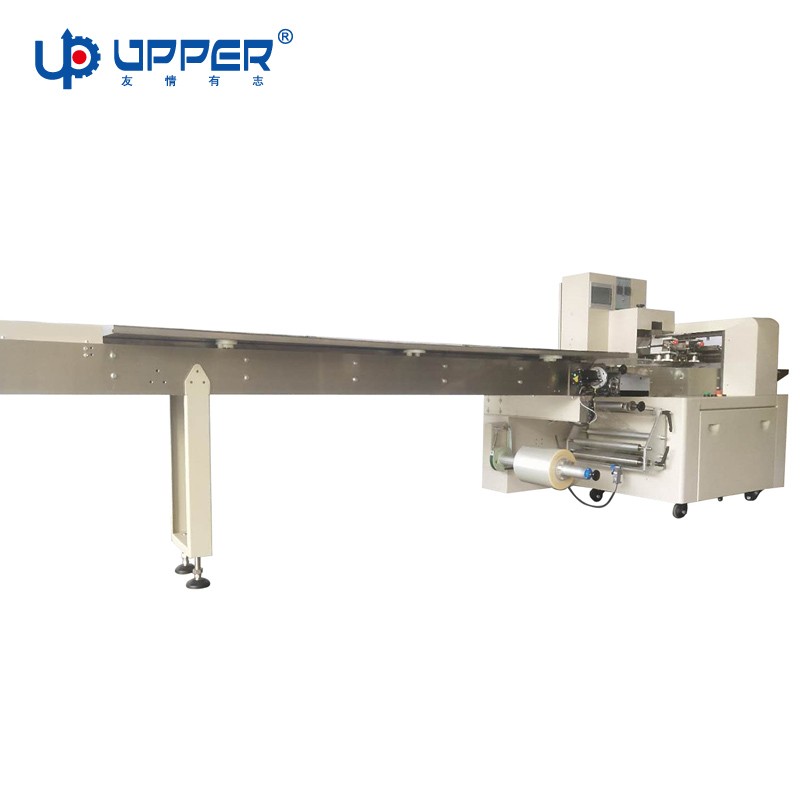

● Candy bar/chocolate bar horizontal flow packing machine

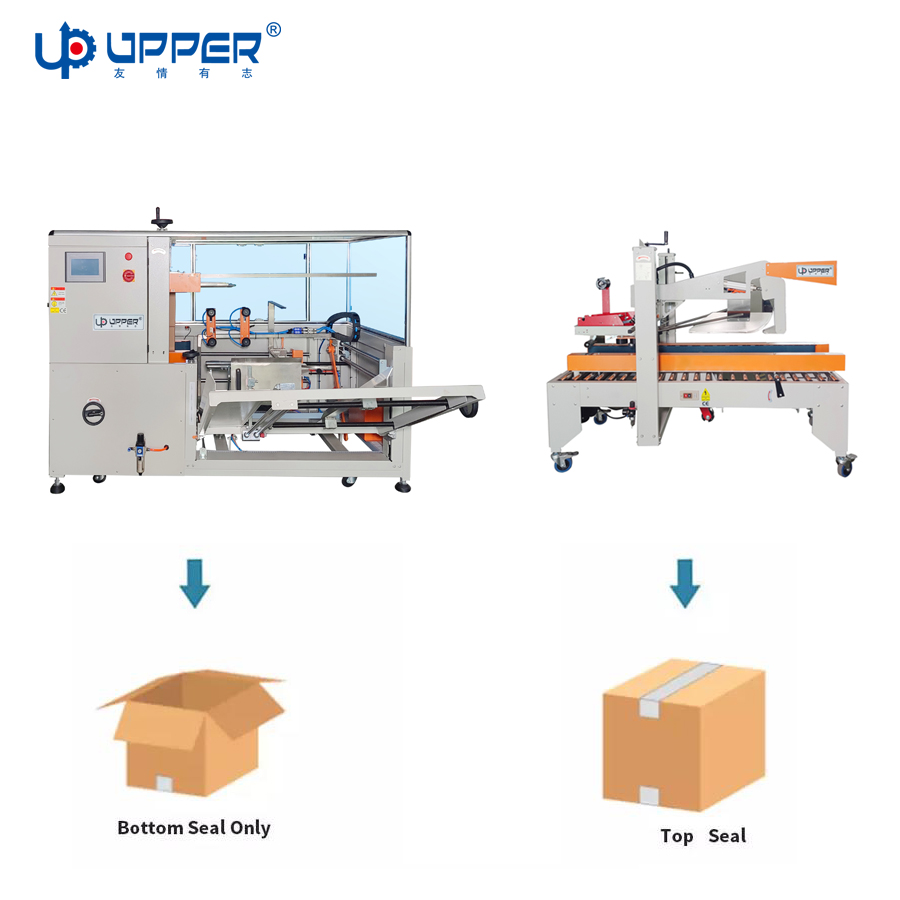

● Candy bar/chocolate bar carton box machine

How to Choose the Automatic Or Semi-auto Candy Bar/Chocolate Bar Packing Machine?

—

Semi-auto candy bar/chocolate bar packaging | Automatic candy bar/chocolate bar packaging |

Small production | Big production capacity |

Manually feeding the candy bar/chocolate bar | Directly connect the candy bar/chocolate bar production machine |

Handling, a certain degree of wear and tear | Hand contact and handling effectively reduce wear |

Operation technicians must be familiar with packaging machinery foundation | Intelligent operation, few manual operations, saving time |

Lower machine cost | Valuable price |

The footprint of the machine is relatively small | Customized footprint |

There Are Two Different Ways to Use the Automatic Candy Bar/Chocolate Bar Packing Machine:

—

● Automatic power baffle candy bar/chocolate bar feeding, connected to the packing line (due to the short bar’s length and high-speed requirement)

● Automatic ascending and sinking candy bar/chocolate bar feeding packing machine (no contact with materials’ packaging)

Check Out Some of Our Past Candy Bars/Chocolate Bars Packing Layout Projects:

—

Please Send Us Your Requirements, We Will Send You CAD Drawings and Quotations Accordingly.

—

● Product incoming methods: such as neat incoming materials, manual pours, scattered incoming materials, preferably with video.

● Product characteristics: fragile, regular, soft, sticky, etc., best with samples pictures.

● Packing method: one pack, two packs up and down, etc., preferably with pictures.

● Production Capacity: how many products per minute?

● What is the requirement for packing speed?

● Do you have requirements for the size of the venue?

Packaging Machine Manufacturer with Decades of Experience

When it comes to your business, ensuring productivity throughout the production line is an integral goal. However, this can often seem challenging, with so many systems being either ineffective or expensive. However, here at Foshan Upper Machinery Equipment Co. Ltd., this was something we knew we could change. As such, we launched our brand to make a tangible, genuine difference for manufacturing businesses just like yours – and we won’t rest until we’ve found the ideal solutions for your manufacturing line needs.

A Long-Standing Passion for Manufacturing

You should never have to settle for second-best when it comes to your packing equipment – and this is something we have always held in mind. With over two decades of experience and expertise in the packing industry, we knew we could make a difference for businesses just like yours. After all, we saw first-hand the challenges that our customers faced, and so we set out to find a new and more reliable solution to this timeless issue.

Delivering Reliable Results for your Manufacturing Goals

Of course, every business is different – so why should your manufacturing equipment be the same as the next brand? During our time in the manufacturing industry, we’ve seen countless times brands having to just “make do” with a solution that’s not optimized to their needs. Fortunately, this was where we knew we could do things a little differently, and so we developed our unique system for customizing orders instead. We bespoke-make every unit based on your business’s requirements, so you enjoy the best solutions accordingly.

After all – why should you have to settle for less than the best?

Product Name | Candy Bar/Chocolate Bar Packaging Machine |

Product Size |

Customized |

Master Conveyor Belt Width | 600/800/1000/mm |

Net Weight | Customized |

Packing Capacity | 50-600 bags/min |

Power Supply | 1Ph-220V50Hz/60Hz or 3Ph-380V50Hz |

Total Power | Customized |

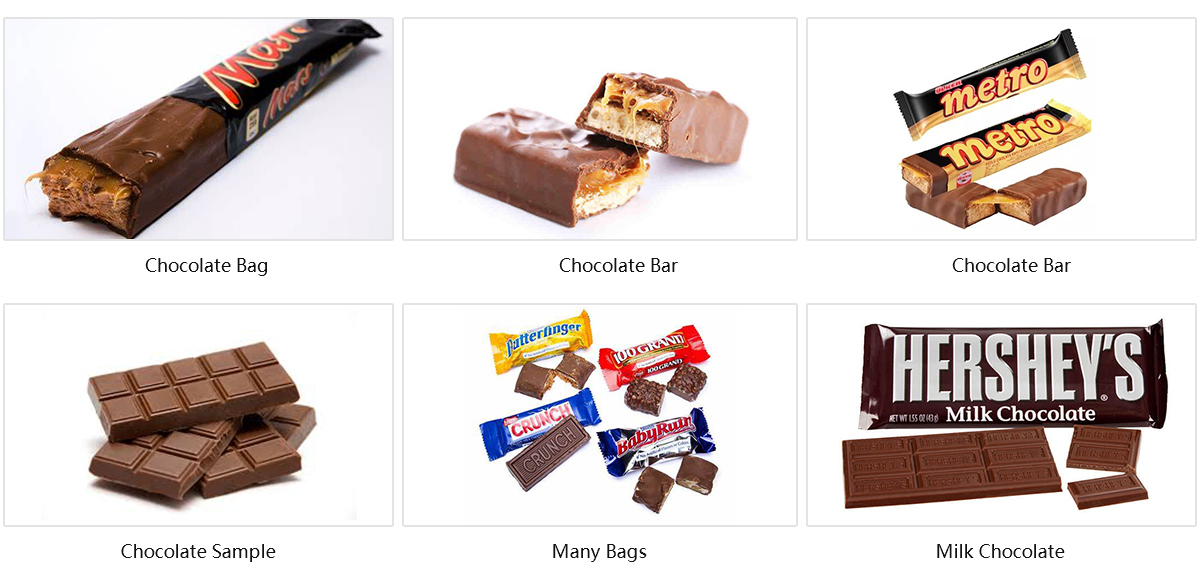

Application

| Mainly applied to chocolate bar and candy bar packing. |

The machine can pack all kinds of solid and regular shapes of the chocolate bar.