Why Choose Us

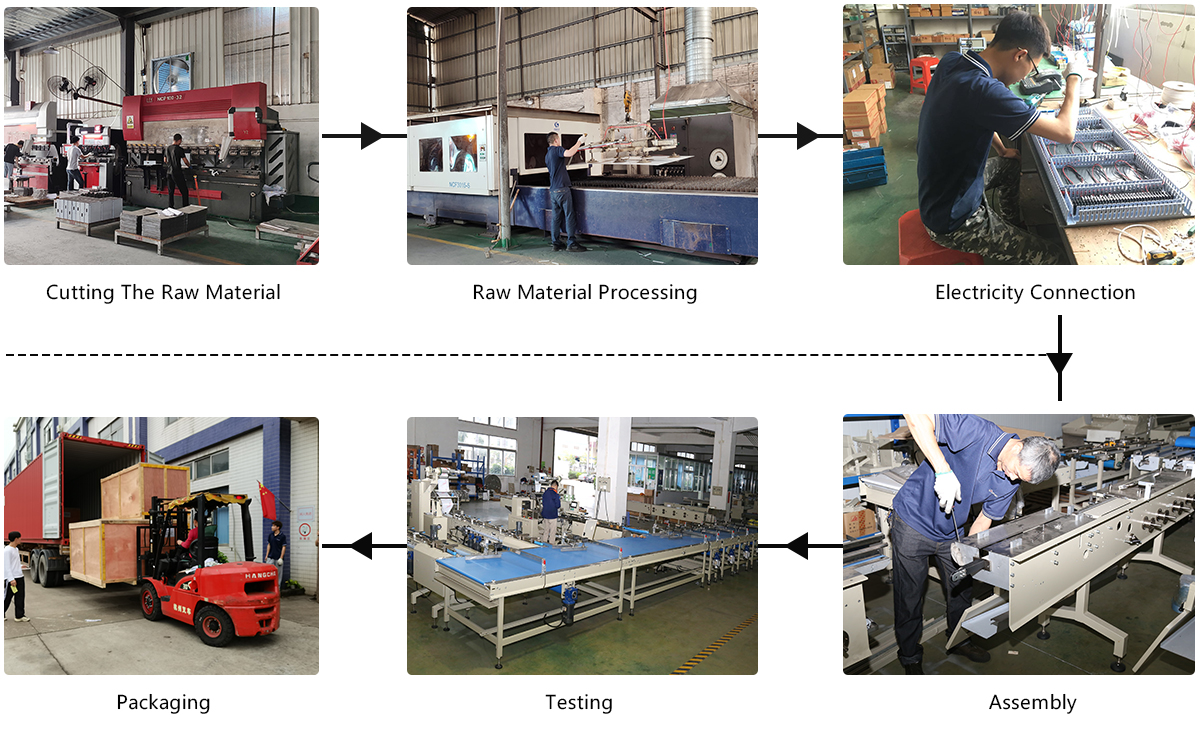

●Upper is a professional factory manufacturer of automatic packing machines.

●Support customized packing machine solutions.

●Engineer teams with over 20 years of experience in packing machines.

●CE, ISO, Quality Assurance Certifications available.

●Machinery with patent certificate.

●High-tech enterprises certificate.

●Fast delivery & professional after-sales service.

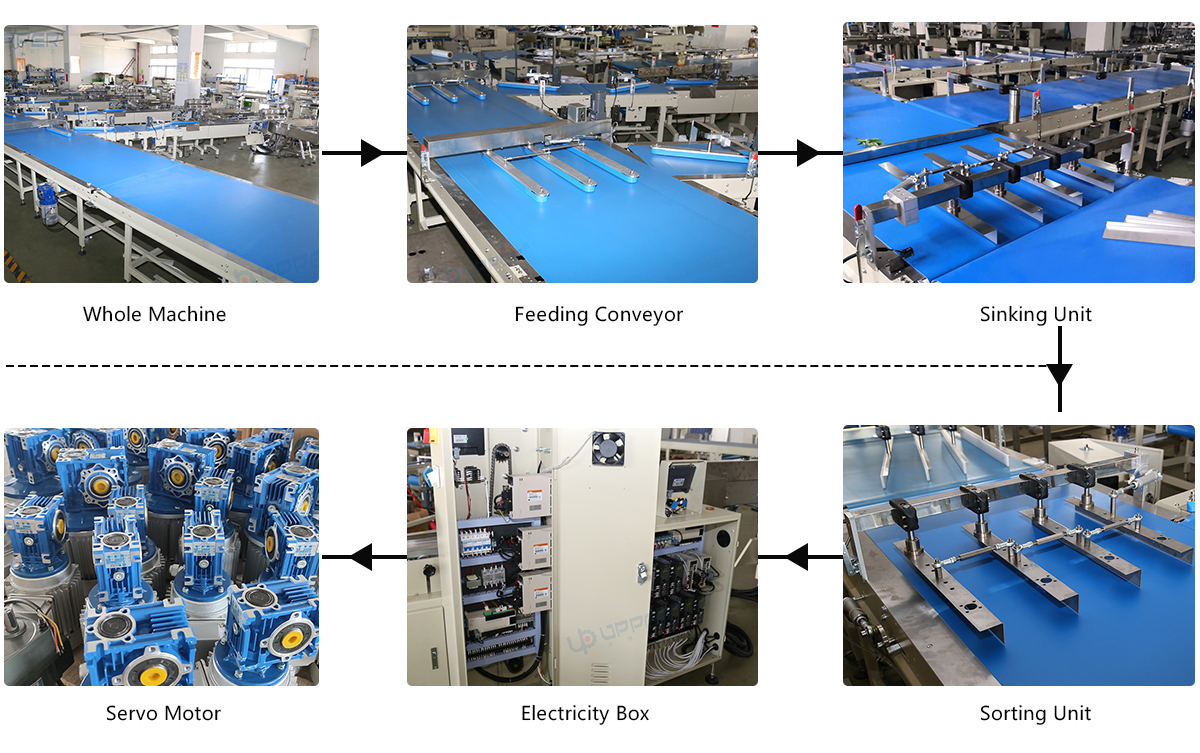

Technical Feactures

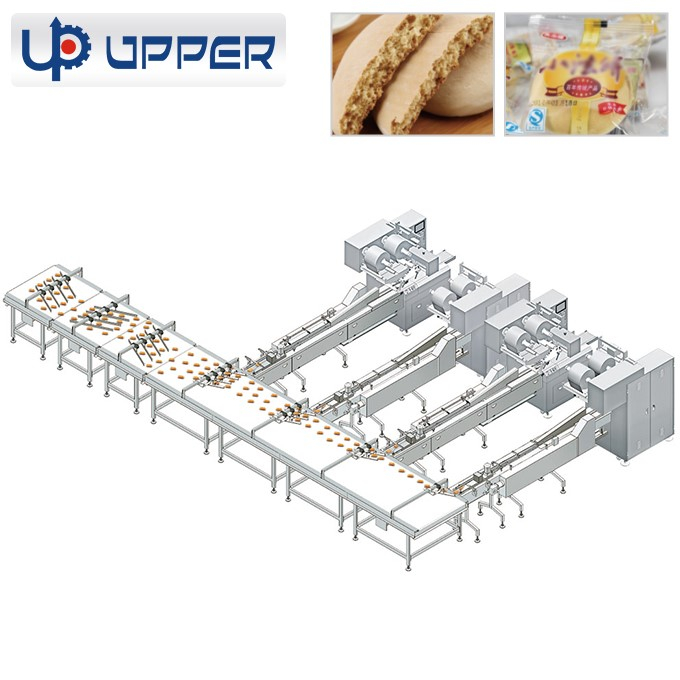

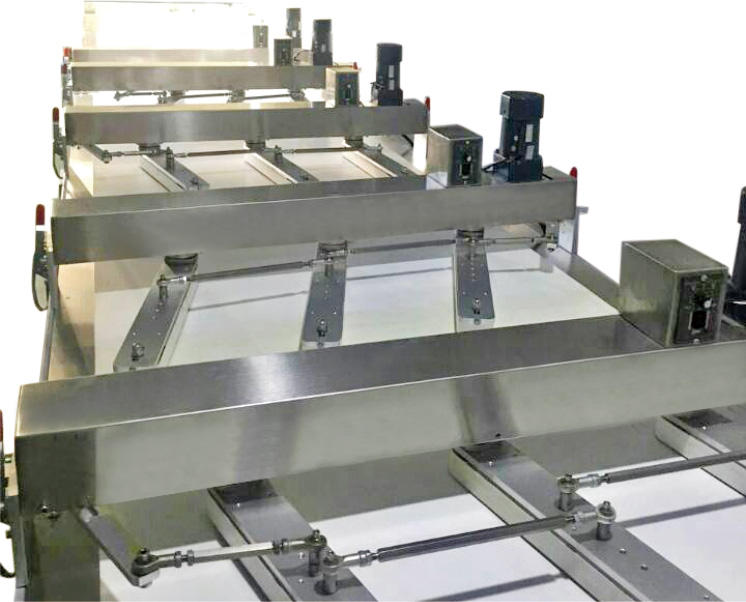

●Automatic packing line suitable for packing the products without in tidy. The packing line conveyor can connect with the production line directory or put the products on the conveyor.

●It can pack bakery products, such as cake, biscuits, bread. And the commodity products like soap.

●Through different speeds to separate the products. Have the photocell detect and the program control to make each line going into the feeding line, through the turn forward device to confirm the products in the correct forward into the feeding line. Through the feeding line to detect the production to confirm the product's exact location, the products coming on the right way into the flow packing machine, the final finished the three side sealing packing.

●We can custom the packing machine as the buyer requested, can add other functions for buyers: such as add the printer, add the air filling device, and two fill roller, automatic film connect the device.

●Our company PLC developed the main control circuit, color touch screen display, inverter control, perfect interface between operator and machine. That makes operation and adjustment easy.

●High-sensitive electric eye functions automatically track bags length accurately, no manual adjustment after setting.

Product Name | Automatic Feeding and Packing Line |

Product Size |

9000×950×1500mm(Customized) |

Packing Capacity | 50-200 bags/min(per single lane) |

Master Conveyor Belt Width | 600/800/1000/1200mm |

Net Weight | Customized |

Power Supply | 1ph-220V-50Hz or 3 ph-380V-50Hz |

Total Power | Customized |