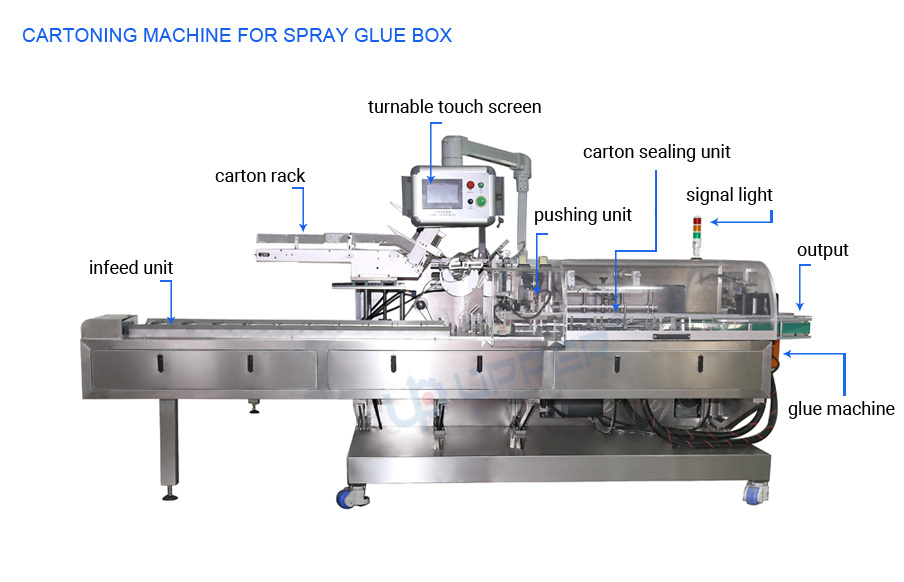

Full Automatic Multifunctional Toilet Soap Bar Cartoning Machine Box Packaging Machine

| Stick Packaging Machine combine working with sorting and cartoning machine STICK PACKAGING, we have released a new type STICKPACKER with Multiple Lane Auger Measuring Unit built in it. This makes it possible to measure/ fill fine or even free flowing powder such as milk, coffee, chocolate, cereal, powdered green tea, pharmaceutical, health food, etc. Weight feedback can be controlled in combination with a check weigher. The machine is servo motor driven which makes product change easy and fast by enabling pre-set of operation condition such as sachet length, filling weight, filling timing, etc. on touch screen panel. Attachable options are Date coder, Reel guider, Nitrogen gas flush, I-notch cutter, Zigzag cutter, cutter adjuster, etc. |

Main Performance And Structure Features:

• Using PLC microcomputer automatic control.

• Use man-machine interface operating system to automatically display performance parameters such as cartoning speed, quantity, and cause of failure,

• The self-lubricating system runs more smoothly.

• The body is made of high-quality stainless steel, baking paint and aluminum

• Multiple specifications can be adjusted and used within the scope of the same equipment.

• Manual and automatic conversion function.

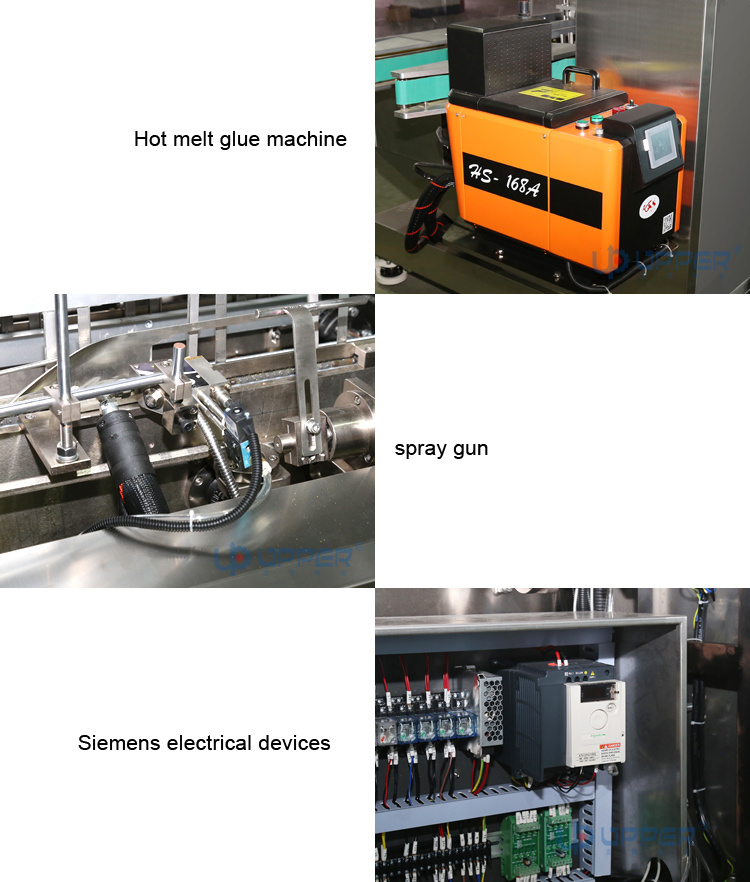

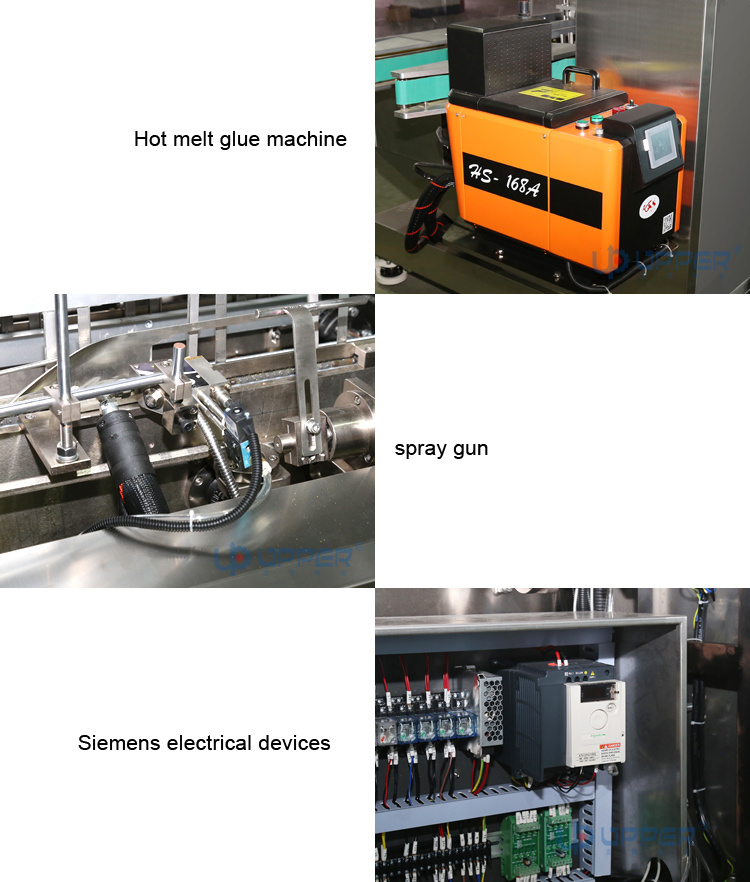

• Can be equipped with hot melt adhesive machine.

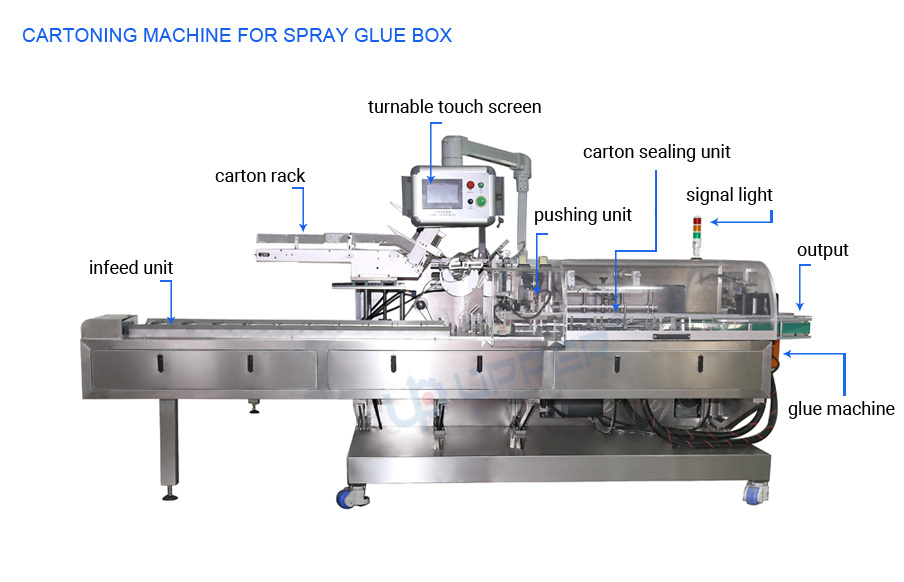

| Mode | UPC-CQX |

| Product name | Horizontal Automatic Cartoning machine |

| Packing speed | Max 80 boxes/min |

| Carton thichness requirement | 250-450 g/m2

(according to its dimension to confirm) |

| Dimension range(L*W*H) | max L 260 *max.W 190* max. 60-70mm

can customize according to your requirement |

| Working pressure | Working pressure: ≥0.6mpa |

| Air consumption | 160-200ml/min |

| Power supply | 380V 50Hz |

| Total power | 1.5 Kw |

| Product size | 5000*1200*1800mm |

| Net Weight | 3000 kg |

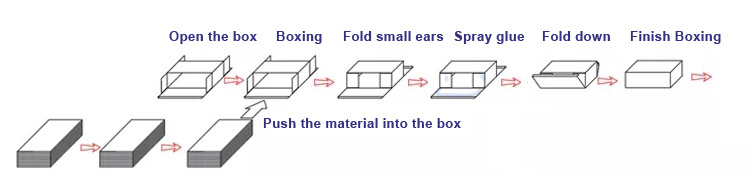

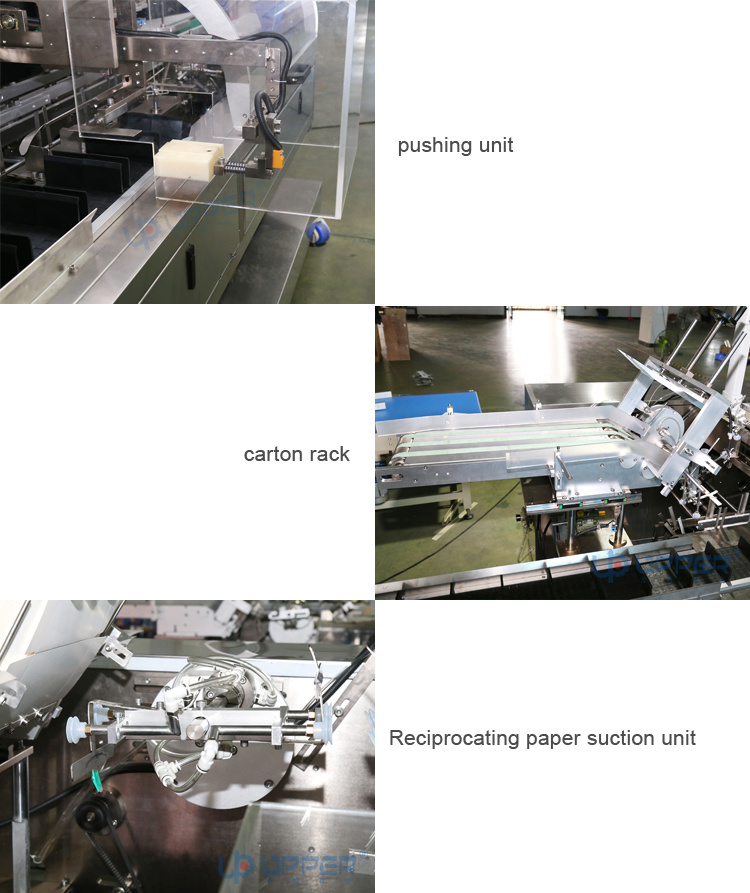

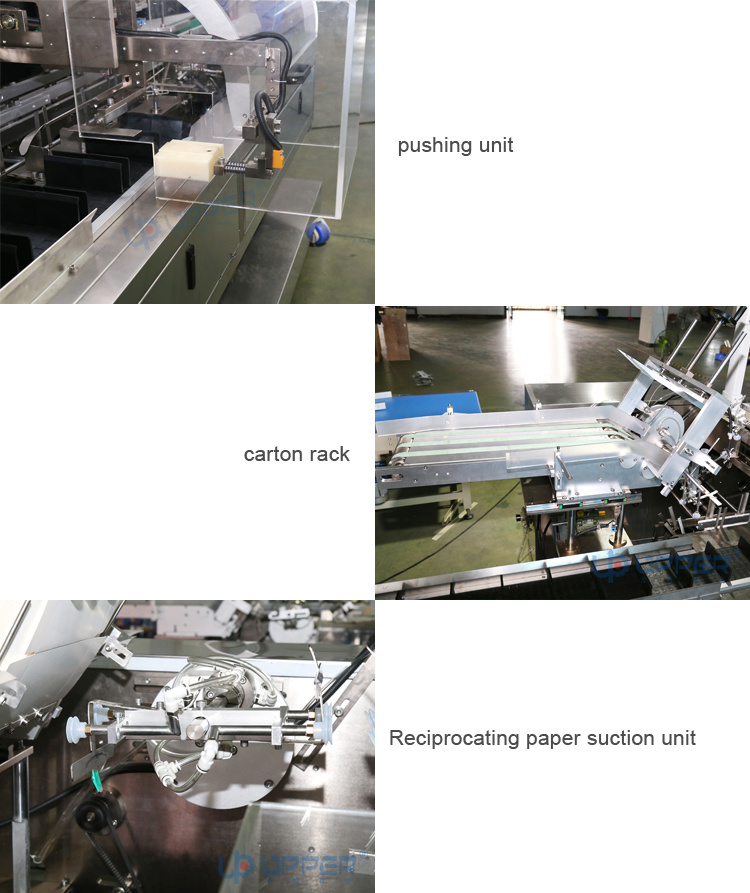

| Introduction: |

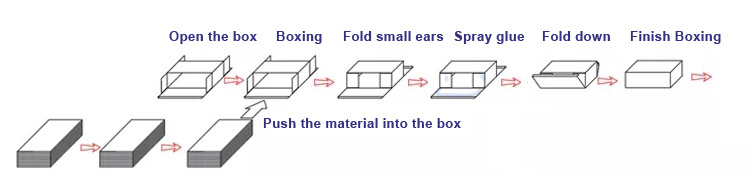

| This cartoning machineis is a fully automatic intermittent horizontal cartoner that automatically open/fold cartons, infeed products, insert leaflet into the cartons, coding and then automatically close the carton. The product range is almost unlimited and encompassing, including pillow bag, blisters, bottle, tubes, etc. |

| Application: |

| Food, medicine, cosmetics, tissues, auto parts and plastic bottles |

| Optional auxiliary equipment/function |

| | Date printer - Ink roll printer, thermal transfer printer, ink jet printer

| Labeling machine

| Deoxidizer sachet feeder

| Seasoning sachet feeder

| Multi-language interface

| Visual Identity System

| Achol spray device

.......

Any other customized function |

| Foshan UPPER machinery equipment co.,ltd locates in Foshan ,Guangdong province ,China. We are professional packaging machinery manufacturer, developed double transducer horizontal packing machine, flow packing machine,and fully automatic feeding and packing line system Since 2011.Our machines are applied to various industries such as: food,hardware, hotel supplies, home supplies, health supplies, office supplies, medical supplies, toies, electrical components and plastic products. We accept both OEM &ODM corporations. Our engineers will make customized design and product developments base on your needs. Quality comes first ,we make 100% strict inspection to all the individual parts before shipment. |

Pre-sale service

1. Training customers' engineers to learn how to use packing machines.

2. Testing packing machines, with product sample and our film materials.

3. Machine testing videos will be sent to customers.

After-sale service

1. Providing manual book.

2. Videos of installation, adjusting, setting, and maintenance are available.

3. Telecommunucations and face to face online communications are available.

4. Engineer oversea services are available. The round-trip air tickets, hotel, meal, and visa cost of our engineers shall be borne by the Buyer.

5. Machine quality guarantee period is 1 year. During guarantee period, if there is no man-made damage, we will replace new ones for you. The guarantee period will start from the date of B/L.

One of our Australia customer, asked for the endineer for the service for the automatic biscuit feeding packing machine. 4 se pillow packing machine + one set feeding machine. Two of our engineers have a good technical service and training service there.

Q1: Do you have manual or operation video for us to know more about the machine?

A1: Sure. Manual and operation video are provided. And drawings are available too.

Q2: What's delivery time for the machine after deposit sent ?

A2: Regular delivery time is 7-10 days for packing machine and 30-45 days for fully automatic packing line upon receipt of deposit.Delivery time will be discussed if machine is customized and additional test needed.

Q3: How you pack the machine before shipment ?

A3:Machine is wrapped by plastic film inside and packed with plywood boxes outside which suitable for sea & air shipments.

Q4: How your factory control the machine quality ?

A4: Quality is our culture. We are always focused on: Professional design. High precision for parts processing.

Q5: Which countries have you ever exported your machines to?

A5: USA, Malaysia,India, Indonesia, Russia, Singapore, Lebanon, Saudi Arabia, Yemen, UAE , Mexico, Chile, Argentina, Brazil, Nigeria, Tunis, Algeria, Egypt, Sudan, Cambodia, Pakistan, Bangladesh,South Korea, Turkey, Uzbekistan and Ukraine.

Q6: How can I trust you for the first time business ?

A6: Please note our above business license and certificate. And if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q7: What's the language used for the operating system ?

A7: English & Chinese are standard, Optional language will be Spanish, Arabic,French, Russian, German...etc.

Q8: What's the warranty period ?

A8: 12 months after shipment for key components except man made damage & fast moving spare parts.

Q9: What about after-sales service ? Is engineer available to serve oversea?

A9: Yes, but the travel fee is paid by you including daily allowance for the technician. So to save your cost, we will send you a video of full details machine installation and assist you till the end. The video covers installation and operation, as well as maintenance.